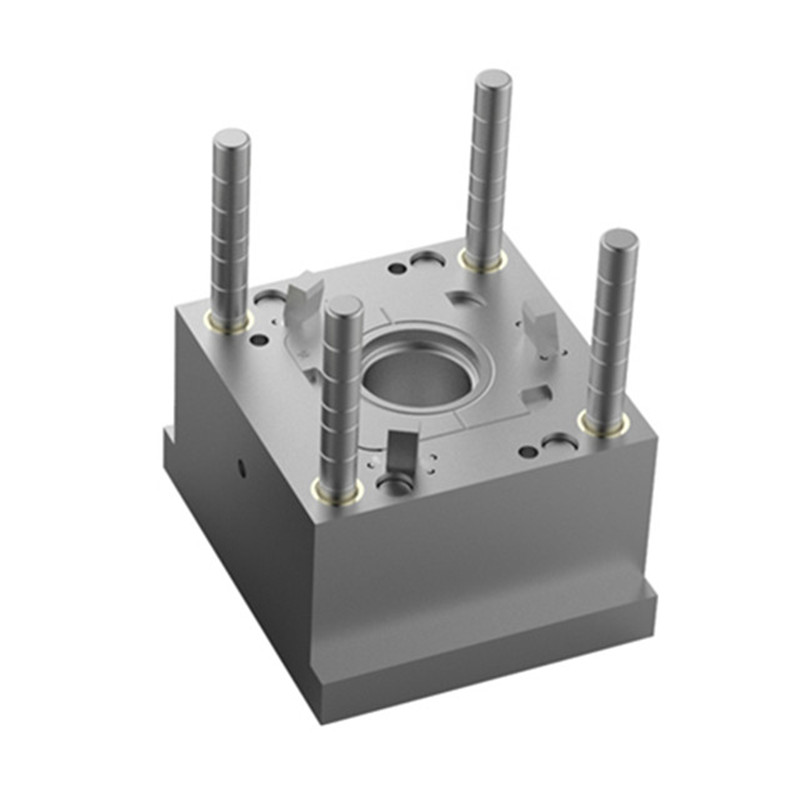

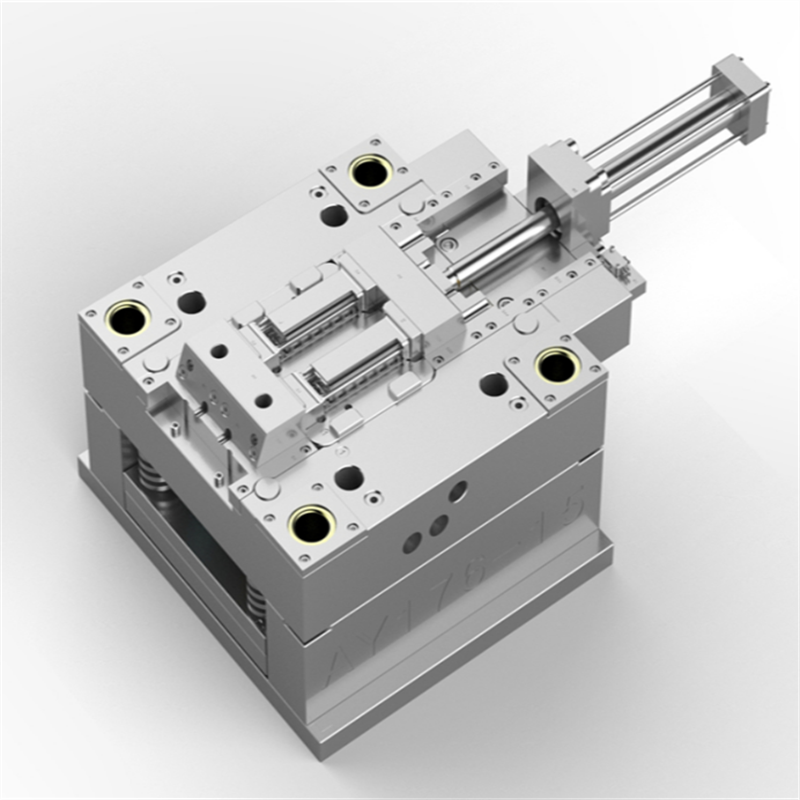

The core & cavity design of the plastic injection mold tooling is what gives the final product its shape, but there are several other functions of the tool that are crucial for the correct formation of the end product. The tool places a large role in the correct cooling down rate of the moulded plastic part. If a plastic material sets at the wrong speed, distortion and stress may occur. The material of the tool should be chosen to keep cooling down rate in mind. Some plastic materials may need to be moulded in a water cooled tool.

View More

Contact Us

Contact Us

IPv6 network supported

IPv6 network supported