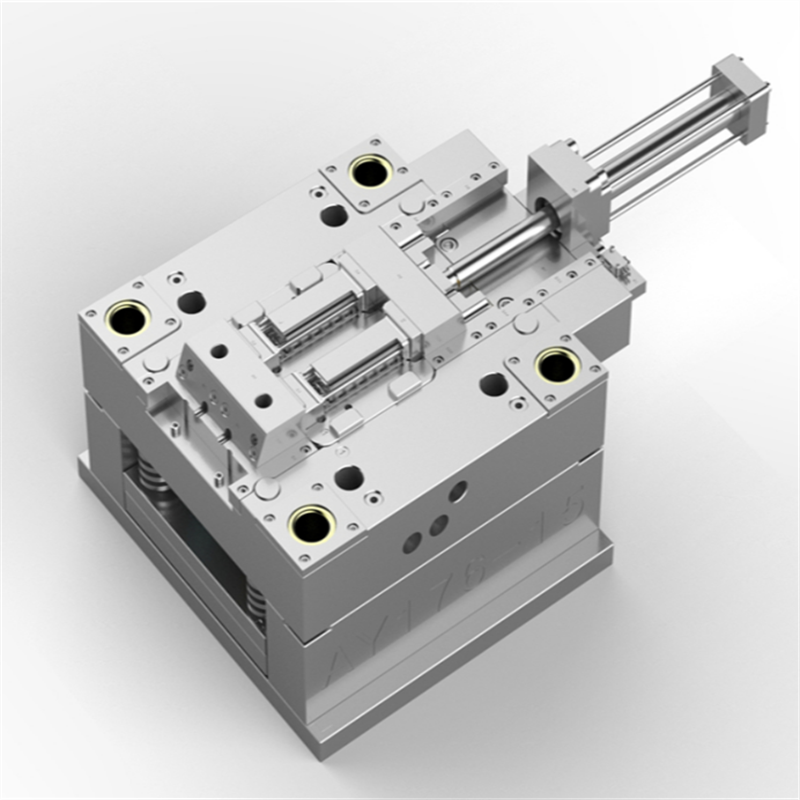

Injection molding is A mold is made based off a CAD file. That's the laborious part of the process as it takes time to create the mold. Such molds are typically made from aluminum or steel.After the mold is created, the thermoplastic resin is injected into it and then left to cure and form the part. The material is first fed into a heated barrel before being launched into the mold to cold and cure.Following curing, the part is removed from the mold and the process starts over until the part run is completed.

View More

Contact Us

Contact Us

IPv6 network supported

IPv6 network supported