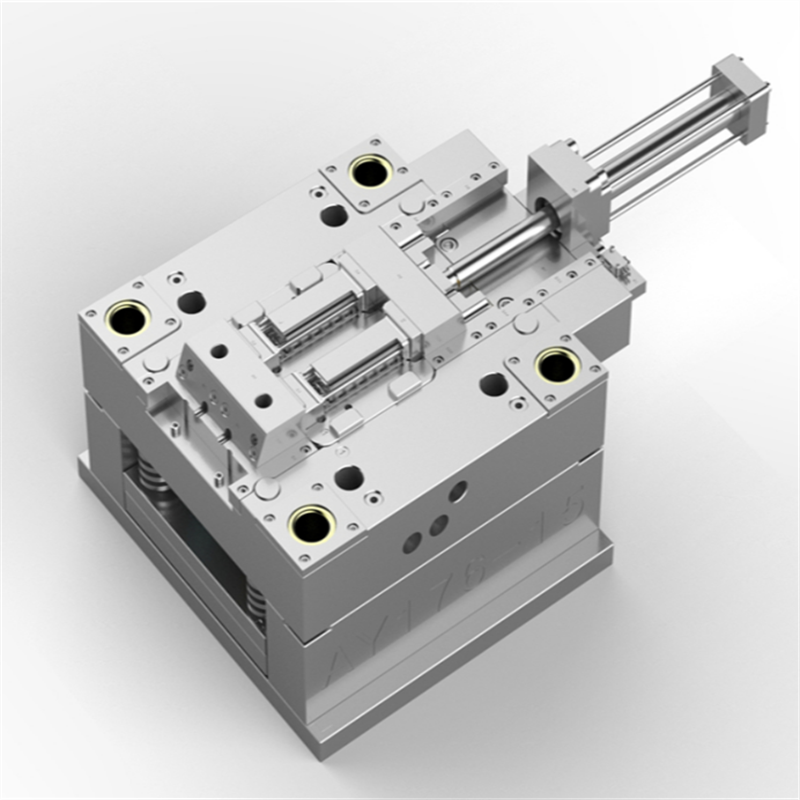

Rubber molding turns uncured rubber and other elastomer materials into usable parts and products. This is achieved by placing a rubber block into a rubber molding metal cavity containing the shape of the desired end product. A combination of heat and pressure activates a chemical reaction, allowing the rubber to cure or vulcanize into the final product. Although there are various ways to perform the custom molded rubber process, they all rely on heat and pressure to form rubber products.

View More

Contact Us

Contact Us

IPv6 network supported

IPv6 network supported