Made of 100% pure silicone, soft to the touch, making it easier to take out ice cubes from the mold; non-toxic and environmentally friendly, no cracking, long service life, much better than ordinary plastic products, no skin irritation, no odor.

This product is made of food-grade silicone rubber, which is environmentally friendly, hygienic, safe and durable. It meets the food hygiene standards of China, the European Union, the United States and other countries. It is a hotel and household product that is popular all over the world.

This product has the following characteristics:

1. The style is novel and varied, which can meet the individual needs of different groups of people.

2. This product can withstand high and low temperature, can work normally in the range of -30℃---+230℃, and can adapt to various refrigerators, ovens, microwave ovens and other electrical appliances to make food.

3. Foods that can be processed by this product include ice cubes, chocolate, cakes, jellies, puddings, biscuits, etc.

4. After finishing the food production, just twist the product, and various shaped foods are ready for you to enjoy.

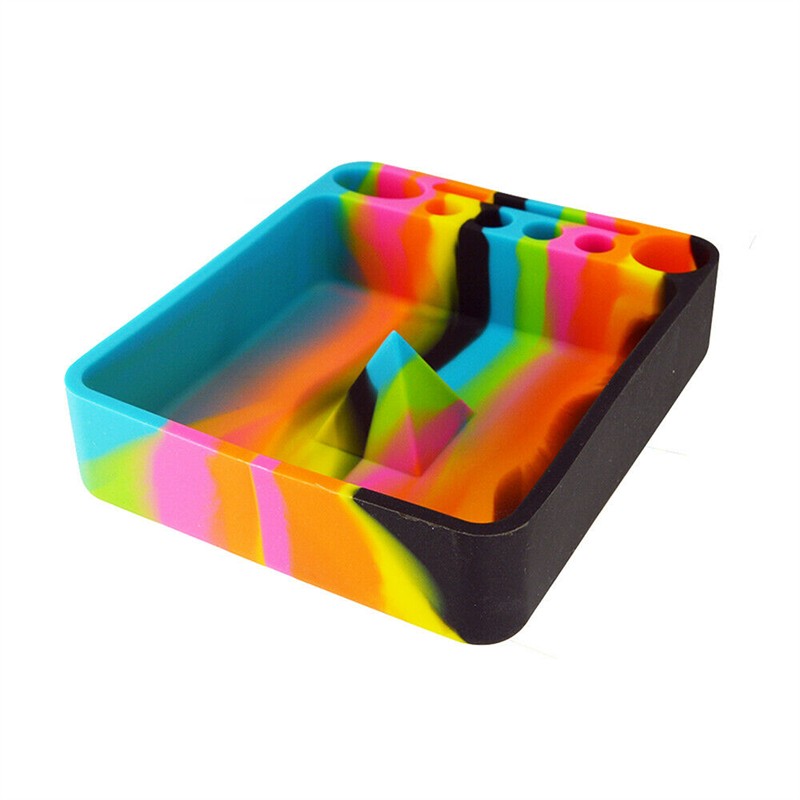

Product shape

The silicone ice ball is a sphere model consisting of two molds. Each sphere has a hole on the top for injecting cold water into it. After freezing, it will naturally form a spherical shape. When the two hemispheres are broken apart, the ice ball will fall off naturally.

Application range

This product can be used to make ice ball, which can cool the body when the weather is hot, or put ice ball into water, drinks, beer, etc. to make them more palatable.

Rubber molded products can be used to create a broad variety of rubber parts ranging from simple to complex.

Learn More

A huge advantage of the processes of making rubber parts is their customizability. With the discussed technologies, engineers enjoy the liberty of designing rubber parts that are unique and best fitted to their products. This enhances user experience, promotes creativity, and boosts your sales.

Learn More

Silicone ice cream tray are made of food-grade silicone, non-toxic and tasteless, temperature-resistant -40°C~230°C, good flexibility, not easy to deform, easy to demould, easy to clean, convenient and durable, can be used to make ice cubes, jelly , pudding, mousse, chocolate, etc., suitable for bars, hotels, restaurants, and home use.

Learn More

Made of 100% pure silicone, soft to the touch, making it easier to take out ice cubes from the mold; non-toxic and environmentally friendly, no cracking, long service life, much better than ordinary plastic products, no skin irritation, no odor. This product is made of food-grade silicone rubber, which is environmentally friendly, hygienic, safe and durable. It meets the food hygiene standards of China, the European Union, the United States and other countries. It is a hotel and household product that is popular all over the world.

Learn More

Waterproof material, moisture-proof and anti-slip professional high-elastic silicone swimming cap, high-quality silicone material. Soft silicone material, more elastic than standard silicone caps, intimate ear protection, double protection, widened protection, leaving room for long hair, non-slip inner design, inner drop-shaped grooves, not easy to fall off after use, comfortable and breathable, not tight head, suitable for swimming training, suitable for long hair Hair wear, suitable for daily swimming.

Learn More

This product is a mosquito repelling silicone wristband made of food grade silicone raw material and natural plant essential oil. The fragrance emitted can play the role of repelling mosquitoes and preventing insect bites. The bracelet itself has a certain tension and softness, and is not easy to deform and has good tear resistance. The product is wear-resistant, high temperature resistant, odorless, has no side effects on the human body, and is suitable for children to wear.

Learn More

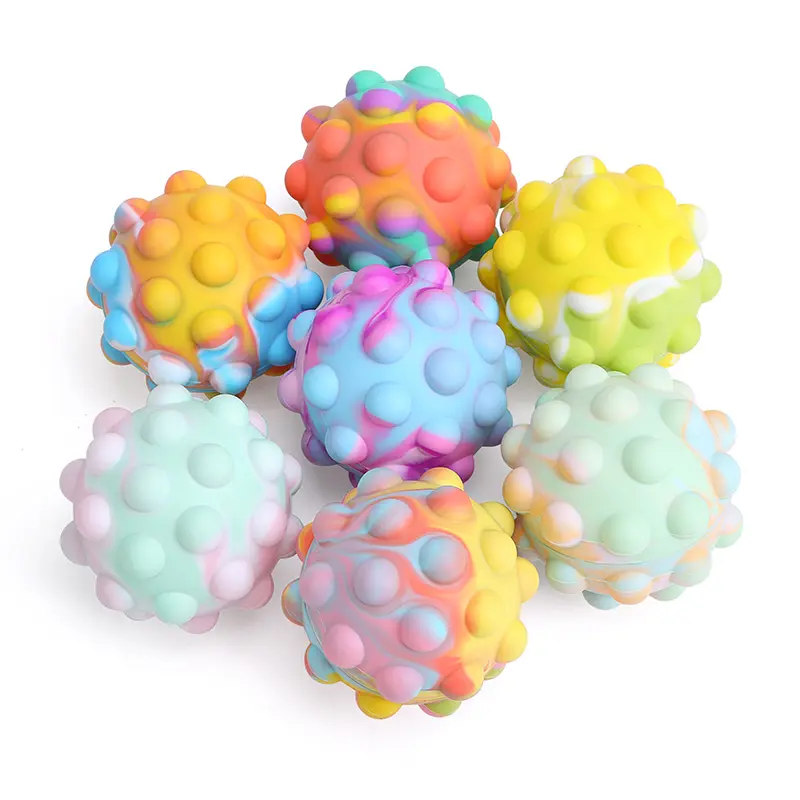

This product is mainly combined with the shape and structure of the ball to hollow out the middle for secondary bonding to achieve the effect of pressing and rebounding. It can be used for hand pinch relaxation and game interaction. The combination of the two achieves multi-functional play.

Learn More

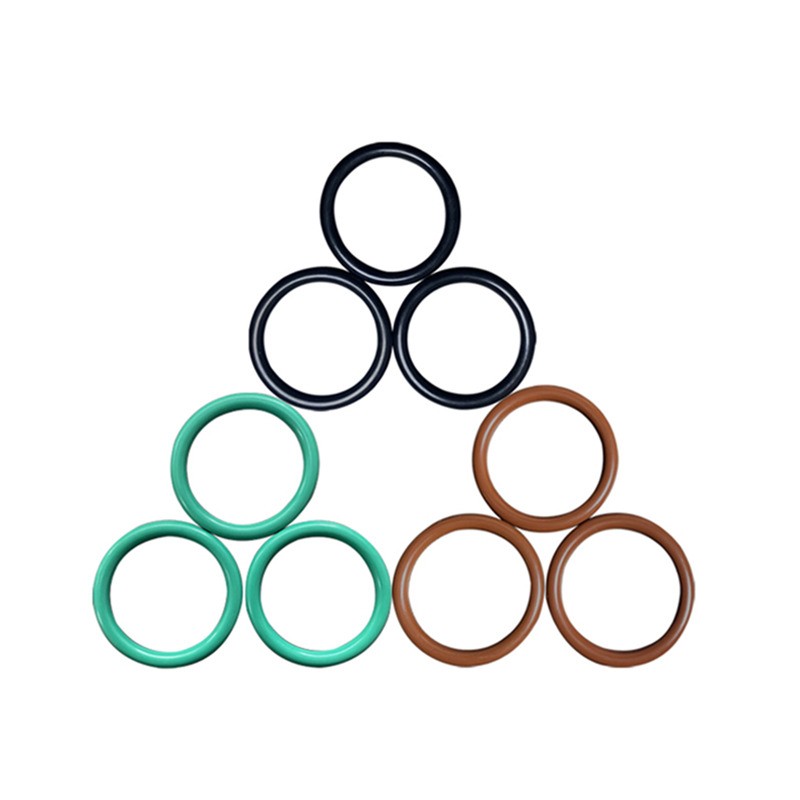

The sealing ring is suitable for installation on various mechanical equipment, and plays a sealing role in the static or moving state under the specified temperature, pressure, and different liquid and gas media. Various types of seals are widely used in machine tools, ships, automobiles, aerospace equipment, metallurgical machinery, chemical machinery, engineering machinery, construction machinery, mining machinery, petroleum machinery, plastic machinery, agricultural machinery, and various instruments and meters.

Learn More

Silicone is a kind of synthetic rubber, and it is the best in synthetic rubber. It is odorless, non-toxic, and is not afraid of high and low temperatures. Silica gel also has good electrical insulation, oxygen resistance and aging resistance, light resistance and aging resistance, mildew resistance, chemical stability and so on. Supplies made of silicone, as long as they are regular products made of regular raw materials, can be used with confidence, so silicone folding water bottle is a good choice.

Learn More

Rubber is an incredibly versatile and durable material. Consumers can find rubber in almost everything that they use on a daily basis. From car tires to pancake-flipping spatulas, rubber is all around. OEMs and manufacturers leverage the traits of rubber in daily operations. The longevity and durability of machinery and equipment can be enhanced by custom rubber parts.

Learn More

Rubber washers is defined as a thin disk made of rubber with a hole in the middle. The washer is normally used to support the weight of a threaded fastener. It is also used as a spacer, spring, wear pad, pre-load indicating device as well as locking device. Washers are made of various materials like metal, plastic, rubber. A common material is rubber. Rubber washers are used in taps or valves where they act as the seal that prevents or closes the flow of liquid or gas. All washers including rubber washers have an outer diameter (OD) about twice their inside diameter (ID). But, washers and gaskets are usually made differently and designed for different functions.

Learn More

Different types of the rubber products are used in automobile for various applications. There are mainly two types of the automotive rubber products. So-called weatherstrip parts fill the space between body and other parts to secure the air tightness, thus preventing water, sound and dust from entry. They also absorb the door opening/closing shock, and prevent vibration, etc. The weatherstrip parts have the important function of improving the outside appearance of automobile from a cosmetic point of view.On the other hand, various functions and performances are required for the so-called hose related parts.

Learn More

By combining two parts from different materials into in one rubber metal parts also enables cost savings in assembly, technical failure and logistical handling. All types of rubber can be combined and adhered to a metal part. Important to guarantee the desired adheson is the preparation and the choice of adhesion system.

Learn More

Rubber washers can make any project go more smoothly and efficient. The rubber washers can be custom designed and will easily fit with any job and machinery. The rubber washers allow for a clean printing and easy stamping, and can be ordered in various colors. For more information about rubber washers, contact us.

Learn More

With the changing dynamics of life there has been a shift in the choice of cookware from being just a reflection of lavish preferences to a mere convenience. One such cookware that has made cooking and baking super convenient is silicone cookware. There's no denying the fact that this cookware makes cooking and baking a lot easier with their unique, flexible texture and moulds.

Learn More

A rubber bellows can be mounted on our gas springs and ensures that the piston rod is protected against impurities and dirt. This protection extends the life of the gas spring. One end of the rubber bellows is attached over the cylinder. The other end is attached to the piston rod just under the thread. The gas spring can still move unhindered and the stroke length is minimally reduced by the distance the rubber is mounted onto the piston rod. The rubber bellows can withstand UV light and oil, and can be used in all types of environment.

Learn More

Rubber grommets are an ideal cost-effective way to protect and cover through holes in many common applications. They help eliminate sharp edges so your wires or sensitive components are protected, greatly reducing the stress and chance for premature failure.

Learn More

Papler industry specialize in supplying high-performance rubber parts- from molded rubber products and rubber extrusions to die-cut and lathe-cut. But, we're much more than a supplier of quality rubber parts. We're a single-source solution.

Learn More

Using rapid prototyping technology, silicone rubber centrifugal casting mold can be easily manufactured, which is suitable for the production of small casting of low melting point alloy with complex shape. Reasonable design of inner runner and OUTLET of casting mold, correct selection of centrifugal casting rotation speed and clamping force of silicone rubber platter are the guarantees of obtaining high quality castings. The centrifugal pouring device of silicone rubber mold has simple structure and low investment.

Learn More

Rubber (rubber mixture) is an indispensable material as an automobile element because of its original characteristics such as big elongation (transformation) and restoration ability which is unattainable by other materials. Rubber is the main raw material for the production of automotive components such as tires, bushes, insulators and seals. All these products have to be safe and wear resistant. Good wear resistance is very important for tire, both in terms of economy and safety.

Learn More

Rubber is a unique material that is both elastic and viscous. Rubber parts can therefore function as shock and vibration isolators and/or as dampers. Although the term rubber is used rather loosely, it usually refers to the compounded and vulcanized material. In the raw state it is referred to as an elastomer. Vulcanization forms chemical bonds between adjacent elastomer chains and subsequently imparts dimensional stability, strength, and resilience. An unvulcanized rubber lacks structural integrity and will “flow” over a period of time.

Learn More

Custom molder for all types of rubber parts. Rubber parts ranging in size from smaller than a pencil eraser to a 24 inch square anti-vibration pad. Examples of capabilities include rubber to metal bonding, colored rubber molding, molded gaskets and seals, rubber protective boots, covers, and sleeves, molded convoluted boots and tubes, custom molded rubber grommets, custom handle grips, custom molded plugs, rubber pedal pads and bumpers. Additional equipment includes secondary die trimming, cryogenic deflashing, and automated vision inspection systems. Design assistance available to help with part design and optimal production process.

Learn More

Rubber Injection Molding is a process in which strips of rubber materials are fed into injection molding machines and cured. In most cases, it is the most efficient way to mold rubber. Rubber injection and injection-transfer molding start with more efficient material preparation. The material is mixed, typically in 500-pound batches, and then stripped immediately after being mixed, into continuous strips measuring approximately 1.25" wide and 0.375" thick. This strip is fed into a screw on the injection molding machines, which charges a barrel with a pre-defined amount of material. When the mold is closed, the material in the barrel is injected into the mold cavities and cured.

Learn More

Rubber Transfer Molding is the process of taking rubber compound or mixed raw material and making "pre-forms" and then compressing the material, forcing it into a cavity where high pressure and temperature vulcanize the rubber to create a new shape.

Learn More

Rubber Compression Molding is the process of taking rubber compounds or mixed raw material and making “pre-forms'' in the shape of the end product and loading them, typically by hand, into an open mold. The mold is closed, the rubber cured, and then demolded—typically by hand. Compression molding is different from transfer molding because the rubber is put directly into the cavities, then compressed rather than being compressed in the pot then transferred into the cavities.

Learn More

Custom Rubber Parts, Customized Service,An extensive line of rubber parts and services allows our customers to meet the needs of a variety of markets, all through one leading supplier.

Learn More

Rubber molding turns uncured rubber and other elastomer materials into usable parts and products. This is achieved by placing a rubber block into a rubber molding metal cavity containing the shape of the desired end product. A combination of heat and pressure activates a chemical reaction, allowing the rubber to cure or vulcanize into the final product. Although there are various ways to perform the custom molded rubber process, they all rely on heat and pressure to form rubber products.

Learn More

An air intake hose from Papler Industry Co.,Ltd is the answer to awkward, rough, and loose connections on your air intake system. Why struggle with wire snips, scissors, tape, and adapters when you could have a custom length air intake hose? Made of high quality rubber, these air intake tubes feature custom sized cuffs to fit the space you need right out of the box.

Learn More

Rubber bellows hose and dust Boots are an essential part of automotive applications and many other industrial systems. Our products can be used in the automotive industry,railway industry (such as high-speed rail, train rail, and MRT rail systems) or motorcycle industry, our manufactured rubber molded parts are used in engine systems, suspension systems, air intake systems, cooling water tanks, and brake parts. Can provide all automotive applications, using injection molding, compression molding, and transfer molding processing technology, the production of the dust cover, rubber bushing, engine mount, intake manifold and other rubber products.

Learn More

Rubber Hose products are extremely versatile tools that have a variety of uses at home, in automobiles, and industrial applications. Whether the task at hand is transporting water, removing dust, or transferring materials, rubber hoses are a smart and economical duct material choice. Choosing the best hose for the job depends on fully understanding the demands of the intended applications.

Learn More

In general, silicone bakeware is heat-resistant, freezer safe, and oven safe, but only up to 428 degrees Fahrenheit or 220 Celsius. It shouldn't be put in the dishwasher, however, and as it doesn't biodegrade and cannot currently be recycled, it's not exactly eco - friendly. Silicone cookware also needs to be dried well before being stored, or it may degrade and develop discoloration and tackiness.

Learn More

Food - grade silicones are increasingly the material of choice for the entire food processing cycle, from large - scale industrial facilities and restaurants to home cooking, as well as in food packaging and labelling. They are convenient, safe, heat resistant, long - lasting, versatile and ensure no modification of food properties and tastes when in contact with food. They are appreciated by food professionals and home cooking as silicone kitchen utensils.

Learn More

Also known as rubber bungs, rubber stoppers are used to seal bottles, tubes and many other containers. They plug containers from the outside without displacing the volume inside. Some more resistant stoppers can also be used for heavy industrial processes. A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware. Stoppers made of cork are also available for this purpose. However, rubber stoppers are preferable for applications that require a tighter seal or a greater degree of chemical resistance.

Learn More

Soft and Flexible Silicone Materials: Non-toxic, food-grade, stain-proof, easy care, machine washable, won't hurt kids.Lightweight Pliable: Various size wildly applicable for most kitchens, bathrooms and laundries.Utilize water pressure principle which sucks down over the drain with ease.Super slim and flat drain stopper design make it seal perfectly with no leakage.Block bad drain odor when not using the tub. Universal size, help to fit most different drains. Easy to clean and can be disinfected in bathroom.

Learn More

Various potential solutions become available through the use of various materials, sizes and designs. Our dust covers for example can be designed single or double convoluted, rubber-only or reinforced with integrated rings at one or both sealing areas. Boots made of TPE have proven to be a superb solution for sealing constant velocity joints for drivelines as well as for automotive steering systems.

Learn More

High Quality Material: Customized sturdy and shatterproof rubber construction with plastic insert, ensure stable connection and long service life. Safety Design: Solid rubber provides protection against various external factors such as drops and shocks, safe and reliable, built-in strain relief prevents the cable from tearing, it meets the standard IP44 protection for use anywhere, even in a humid environment. Suitable for assorted wire size: Our male electrical plug is suitable for wires of different sizes from 6 mm, 9 mm, 12mm, 16mm, the rubber tip can be cut according to the size of the cable diameter. Multiple application: the protective contact socket is widely used in commercial and construction sites, private outdoors or indoors, ideal for connecting to outdoor extension cords or for tying and repairing damaged power cables.

Learn More

A stopper is plug or a cork — it's designed to block the opening of a container by fitting partially inside it. The rubber plug you use to keep your bath water from going down the drain is a type of stopper. The cork in the neck of a wine bottle is a stopper . Other kinds of stoppers halt or prevent something. A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware. Stoppers made of cork are also available for this purpose. However, rubber stoppers are preferable for applications that require a tighter seal or a greater degree of chemical resistance.

Learn More

Silicone rubber compounds have characteristics of both inorganic and organic materials, and offer a number of advantages not found in other organic rubbers. Silicone rubbers have fine electrical properties, good chemical stability and flame retardancy, and superior resistance to heat and cold. Valued for their electrical-insulating properties, chemical stability, and the wide temperature range over which they retain resiliency, silicone rubbers are used mainly in O-rings, heat-resistant seals, caulks, gaskets, electrical insulators, flexible molds, and (owing to their chemical inertness) surgical implants.

Learn More

A rubber bushing sometimes simply called a bushing, is a kind of vibration isolator. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms. Typically, they are fashioned into an annular cylinder shape and are encased in metal cases or in outer tubes. In other applications, the bushings have an internal crush tube which protects them from being crushed.

Learn More

The use of rubber bushings is often preferable to solid connections as noise and vibration are lessened. They can also eliminate the use of lubrication between two parts. Used in the suspension system of vehicles, rubber bushings can adversely affect vehicle performance, especially the handling during cornering and breaking. Rubber bushings are widely used in the production of vehicles. Typically, they are found in anti-roll bars, shock absorber mountings, double wishbone suspensions, gear sticks and in the internal combustion engines of some cars.The use of rubber bushings in vehicles can be credited to Walter Chrysler, who encouraged the use of rubber vibration isolating mounts, cutting down both vibration and noise especially when the vehicle already has a load. Eventually, rubber bushings were used in parts that generated vibration and noise. They are also used in skateboards where they aid in the tilting of the trucks and turning the board. Rubber bushings may also be used to help transfer load from one area in a structure to another, thus reducing strain. These bushings can also be used as shock absorbers, vibration insulators and abrasion resistors. Used with wires, pipes and tubings, rubber bushings can act as seals. Rubber grommets are similar to bushings and are also used in a variety of functions. One of the most common functions of grommets is to protect eyelets from wear and tear as parts or objects pass through these. They may also be used in wires, rods and pipes that go through firewalls and plates, acting as seals.

Learn More

At Papler Industry, we produce hot vulcanized and molded O-rings and encapsulated type rings. Vulcanized rings are cost effective, and can be produced in a wide range of diameters, delivering a flexible but strong joint. Molded rings are ideal for precision applications. Our O-rings are produced on clamshell molding equipment by some of the most experienced personnel in the industry.

Learn More

A rubber bushing sometimes simply called a bushing, is a kind of vibration isolator. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms. Typically, they are fashioned into an annular cylinder shape and are encased in metal cases or in outer tubes. In other applications, the bushings have an internal crush tube which protects them from being crushed.

Learn More

A stopper is plug or a cork — it's designed to block the opening of a container by fitting partially inside it. The rubber plug you use to keep your bath water from going down the drain is a type of stopper. The cork in the neck of a wine bottle is a stopper . Other kinds of stoppers halt or prevent something. A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware. Stoppers made of cork are also available for this purpose. However, rubber stoppers are preferable for applications that require a tighter seal or a greater degree of chemical resistance.

Learn More

Molding convolutes in rubber and molding rubber bellows takes special know-how, and Custom Rubber Corp. has it. We're experts in designing molds for any shape and size rubber bellows to cover different ranges and directions of motion. Time and again, major manufacturers have counted on our experience to design rubber convoluted boots and rubber bellows that not only protect, but simplify end-product assembly. For example, we've developed rubber compounds with extra elongation and our own special tooling so that a convoluted boot or bellows can be made with a wide-diameter center, but small stay-tight ends—with no tearing.

Learn More

Simple,flexible mountings for small machinery installations offering a high degree of vibration isolation in machinery that vibrate due to rotating parts like compressors,fans,motors,HVAC equipments. Offering a high degree of deflection ensures vibration reduction for control panels, measuring instruments, navigational equipments and other portable machinery or equipments. Sturdy construction,corrosion resistance,low cost mountings ideal for installations in space restricted applications.

Learn More

Rubber has become ever more popular compared to a traditional leather option, and they are also more comfortable on the wrist than metal bands. They generally offer a more sporty look which is fit for an everyday casual look, and can make for a great modern watch.

Learn More

Have you selected the most appropriate elastomer of rubber for your project? Be it Neoprene, Silicone, Viton, Nitrile, EPDM or any other elastomer, our team of senior consultative sales engineers will provide you with the information required for you to determine which elastomer will meet or exceed your toughest requirements. Papler Industry can supply almost any elastomer on the market today, using compression, transfer, standard injection and liquid injection molding processes.

Learn More

Silicone is known for its retention of flexibility and low compression set in extreme heat or cold. Silicone rubber is very durable and overall, has good mechanical properties. Because of its durability, it is extremely reliable and can be trusted to keep up performance for a long time.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicone moulding (molding) is a manufacturing technique used to transform uncured (unvulcanized) silicone rubber into a pre-defined shape. Several moulding techniques may be used, including compression, injection, and liquid injection. Platinum catalyst silicone molds (like our Food Grade silicone or silicone putty) last 20+ years when stored properly. Latex molds last 10-20 years when stored properly. Urethane rubber molds (like our 75A urethane rubber) last 20+ years when stored properly.

Learn More

Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, silicone rubber, silicone resin, and silicone caulk. Silicon metal is made from the reaction of silica (silicon dioxide, SiO2) and carbon materials like coke, coal and wood chips. Silica is typically received in the form of metallurgical grade gravel. The silicone-making process involves extracting silicon from silica and passing it through hydrocarbons. It's then mixed with the other chemicals to create silicone.

Learn More

Silicones are used in sealants, adhesives, lubricants, medicine, cooking utensils, thermal insulation, and electrical insulation. Some common forms include silicone oil, silicone grease, silicone rubber, silicone resin, and silicone caulk. Silicon metal is made from the reaction of silica (silicon dioxide, SiO2) and carbon materials like coke, coal and wood chips. Silica is typically received in the form of metallurgical grade gravel. The silicone-making process involves extracting silicon from silica and passing it through hydrocarbons. It's then mixed with the other chemicals to create silicone.

Learn More

What is Rubber? Rubber is a polymer which can stretch and shrink. It occurs naturally and can be synthesized as well. We have been using rubber products since ancient times. But during the 19th century it became a highly useful industrial raw product for various purposes. Types of Rubber Rubber can be divided into following two types based on its origin – Natural Rubber Synthetic Rubber There is a wide variety of synthetic rubber available such as EPDM (Ethylene Propylene Diene Monomer) rubber, commercial black rubber, SBR (Styrene butadiene rubber), NBR (nitrile butadiene rubber), IIR (Isobutylene-isoprene) etc.

Learn More

What is Rubber? Rubber is a polymer which can stretch and shrink. It occurs naturally and can be synthesized as well. We have been using rubber products since ancient times. But during the 19th century it became a highly useful industrial raw product for various purposes. Types of Rubber Rubber can be divided into following two types based on its origin – Natural Rubber Synthetic Rubber There is a wide variety of synthetic rubber available such as EPDM (Ethylene Propylene Diene Monomer) rubber, commercial black rubber, SBR (Styrene butadiene rubber), NBR (nitrile butadiene rubber), IIR (Isobutylene-isoprene) etc.

Learn More

What is Rubber? Rubber is a polymer which can stretch and shrink. It occurs naturally and can be synthesized as well. We have been using rubber products since ancient times. But during the 19th century it became a highly useful industrial raw product for various purposes. Types of Rubber Rubber can be divided into following two types based on its origin – Natural Rubber Synthetic Rubber There is a wide variety of synthetic rubber available such as EPDM (Ethylene Propylene Diene Monomer) rubber, commercial black rubber, SBR (Styrene butadiene rubber), NBR (nitrile butadiene rubber), IIR (Isobutylene-isoprene) etc.

Learn More

What is Rubber? Rubber is a polymer which can stretch and shrink. It occurs naturally and can be synthesized as well. We have been using rubber products since ancient times. But during the 19th century it became a highly useful industrial raw product for various purposes. Types of Rubber Rubber can be divided into following two types based on its origin – Natural Rubber Synthetic Rubber There is a wide variety of synthetic rubber available such as EPDM (Ethylene Propylene Diene Monomer) rubber, commercial black rubber, SBR (Styrene butadiene rubber), NBR (nitrile butadiene rubber), IIR (Isobutylene-isoprene) etc.

Learn More

Rubber bushings are effective in reducing the transmission of shock and vibration between parts. In the automotive industry, there are many advantages of using rubber on shock absorbers, including improved safety and comfort when driving, minimised noise and damage due to reduced vibration. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms.

Learn More

Rubber bushings are effective in reducing the transmission of shock and vibration between parts. In the automotive industry, there are many advantages of using rubber on shock absorbers, including improved safety and comfort when driving, minimised noise and damage due to reduced vibration. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms.

Learn More

Rubber bushings are effective in reducing the transmission of shock and vibration between parts. In the automotive industry, there are many advantages of using rubber on shock absorbers, including improved safety and comfort when driving, minimised noise and damage due to reduced vibration. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms.

Learn More

Rubber bushings are effective in reducing the transmission of shock and vibration between parts. In the automotive industry, there are many advantages of using rubber on shock absorbers, including improved safety and comfort when driving, minimised noise and damage due to reduced vibration. Its main purpose is to serve as an interface between two parts, acting as a buffer and absorbing some of the energy produced by the interaction of two parts. It separates two parts while allowing a limited amount of movement, thus minimizing vibration and even noise. Rubber bushings come in a variety of forms.

Learn More Contact Us

Contact Us Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China

Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China WhatsApp : +86 18259211580

WhatsApp : +86 18259211580 Email : roger@ppl2009.com

Email : roger@ppl2009.com IPv6 network supported

IPv6 network supported