Metal stamping is a complex process that can include a number of metal parts stamping forming processes —blanking, punching, bending, and piercing and more.

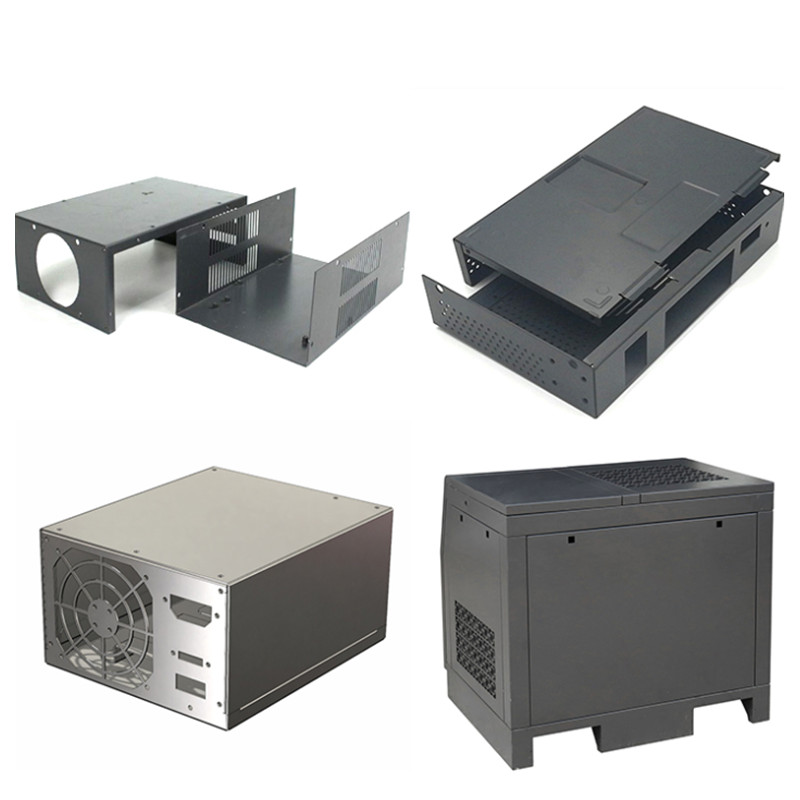

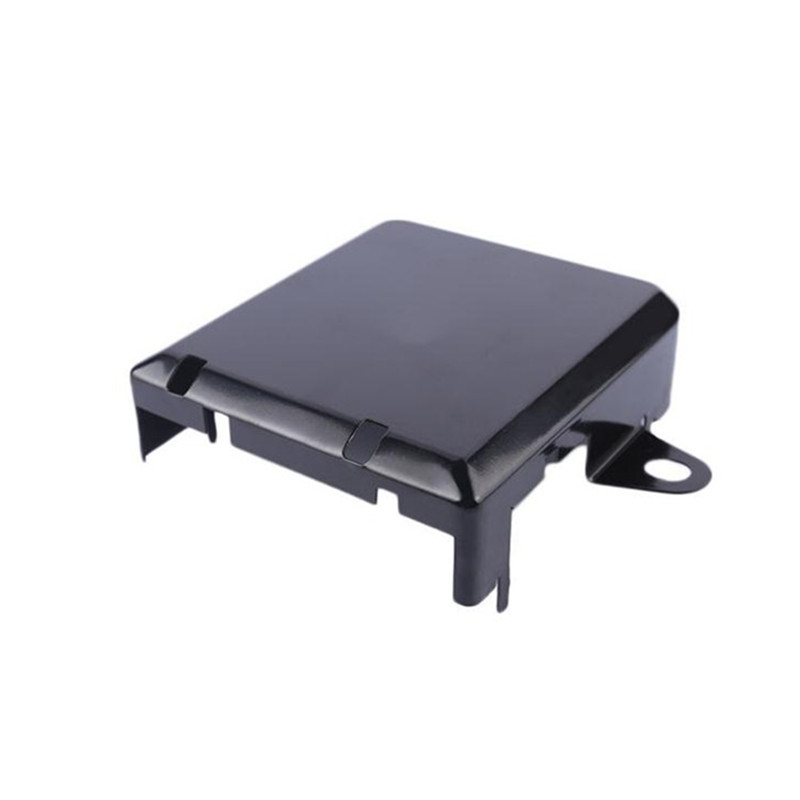

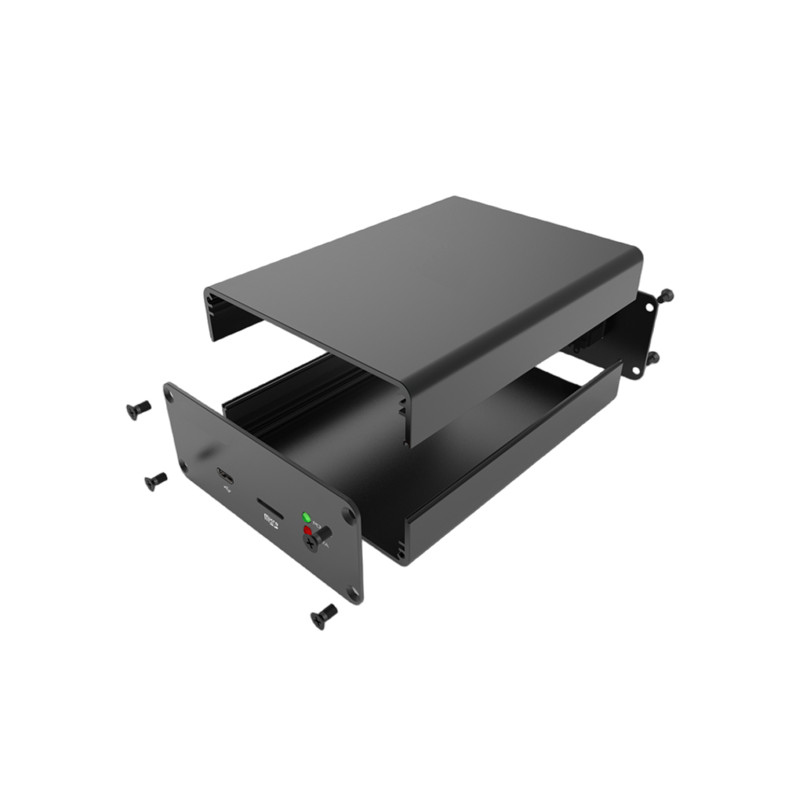

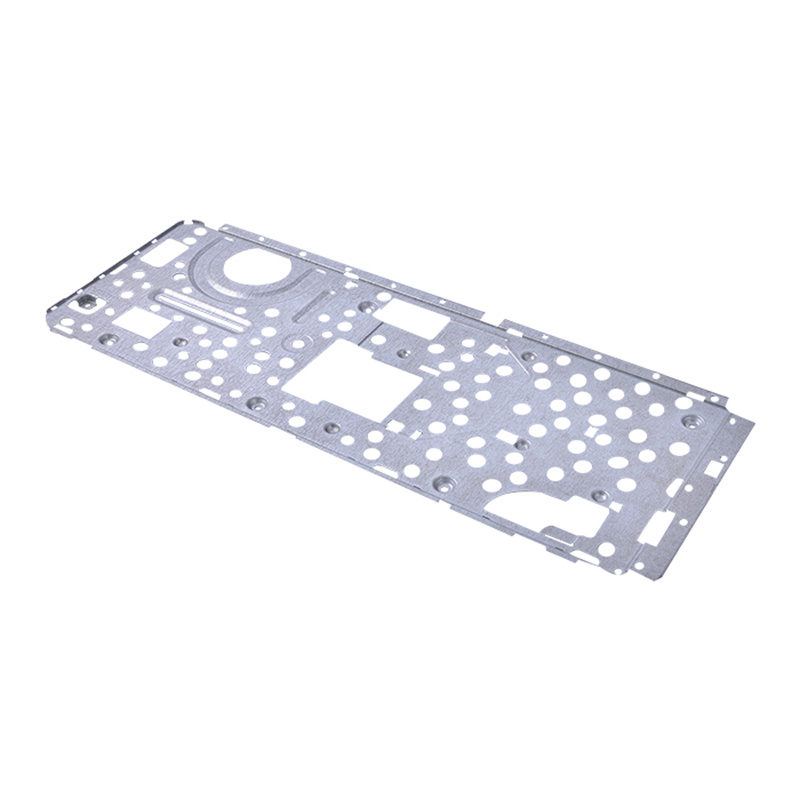

Good Professional Stamping Parts FactPory Computer Case Sheet Metal Stamping Parts

Fourslide Stamping

Fourslide, or multi-slide, involves horizontal alignment and four different slides; in other words, four tools are used simultaneously to shape the workpiece. This process allows for intricate cuts and complex bends to develop even the most complex parts.

Fourslide metal parts stamping can offer several advantages over traditional press stamping that make it an ideal choice for many applications. Some of these advantages include:

Versatility for more complex parts

More flexibility for design changes

As its name implies, a fourslide has four slides — meaning that up to four different tools, one per slide, can be used to achieve multiple bends simultaneously. As material feeds into a fourslide, it is bent in quick succession by each shaft that is equipped with a tool.

Stamping processing is a commonly used processing method, which is mainly used for processing metal and non-metal sheet metal parts. Stamping processing is generally carried out at room temperature, so it can also be called cold stamping.

Learn More

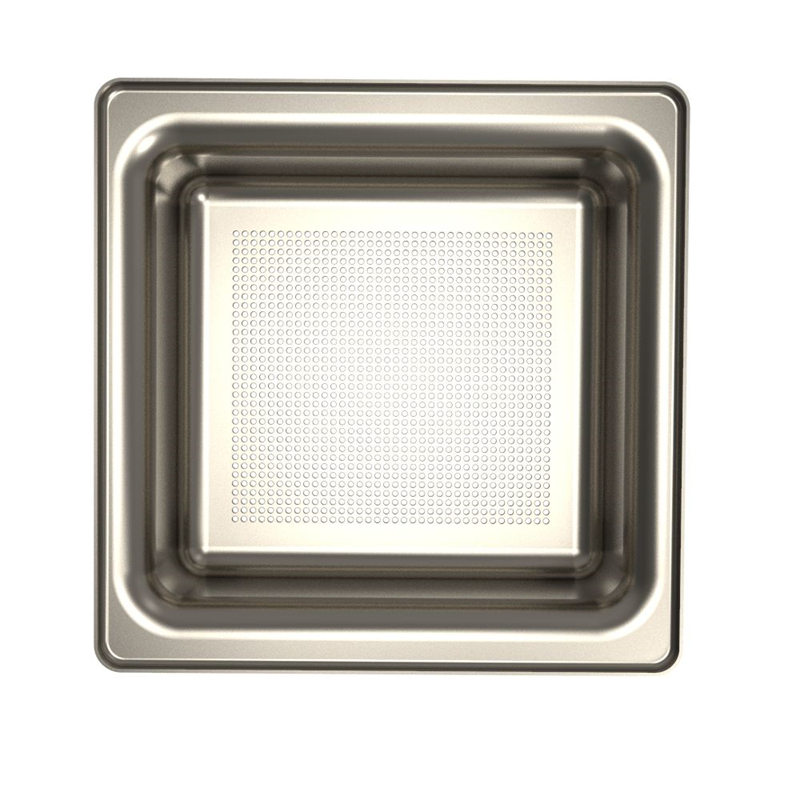

The stamping method can be used to obtain workpieces with complex shapes and difficult processing, such as thin shell parts. The dimensional accuracy of the stamping parts is guaranteed by the mold, so the dimensions are stable and the interchangeability is good.

Learn More

The stamping method can be used to obtain workpieces with complex shapes and difficult processing, such as thin shell parts. The dimensional accuracy of the stamping parts is guaranteed by the mold, so the dimensions are stable and the interchangeability is good.

Learn More

The mold structure used in stamping processing is generally more complicated, the production cycle is longer, and the cost is higher. Therefore, the use of stamping technology in single-piece and small-batch production is subject to certain restrictions. The stamping process is mostly used in batch and mass production.

Learn More

The mold structure used in stamping processing is generally more complicated, the production cycle is longer, and the cost is higher. Therefore, the use of stamping technology in single-piece and small-batch production is subject to certain restrictions. The stamping process is mostly used in batch and mass production.

Learn More

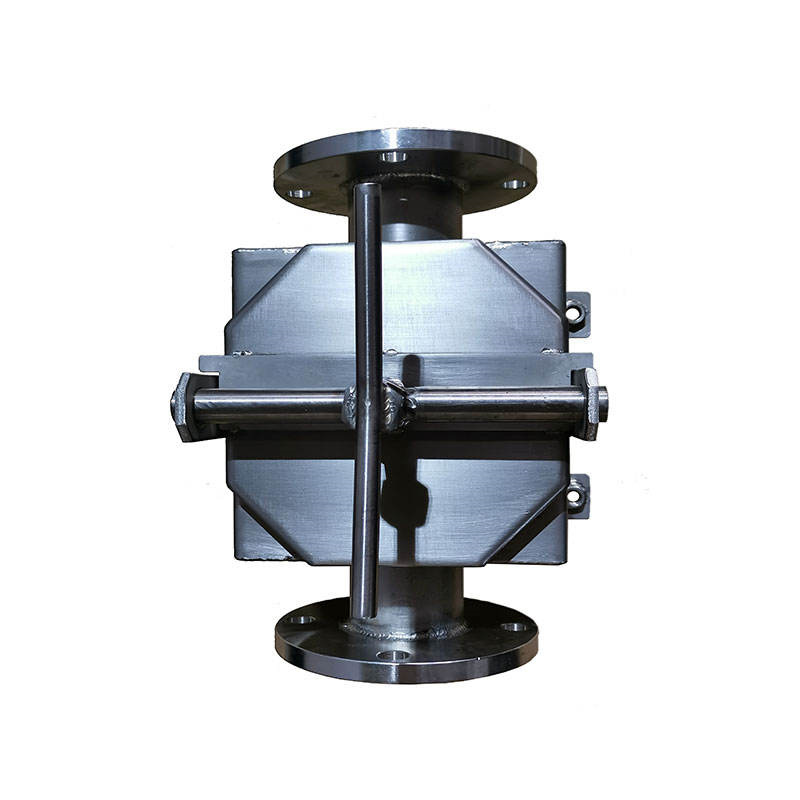

The stamping process is a metal processing method, which is based on the plastic deformation of the metal, using the mold and stamping equipment to exert pressure on the sheet, so that the sheet is plastically deformed or separated, so as to obtain a certain shape, size and performance. parts (stamping parts).

Learn More

The stamping process is a metal processing method, which is based on the plastic deformation of the metal, using the mold and stamping equipment to exert pressure on the sheet, so that the sheet is plastically deformed or separated, so as to obtain a certain shape, size and performance. parts (stamping parts).

Learn More

Stamping is a method of forming and processing workpieces (stamping parts) of required shape and size by applying external force to plates, strips, pipes and profiles by presses and molds to cause plastic deformation or separation. Compared with castings and forgings, stamping parts have the characteristics of thinness, uniformity, lightness and strength. Stamping can produce workpieces with ribs, ribs, undulations or flanges that are difficult to manufacture by other methods to increase their rigidity.

Learn More

Sheet metal stamping is to apply external pressure to various materials such as metal sheets, metal pipes, metal bars, etc. through hydraulic or mechanical presses by means of stamping dies, so as to deform and separate the metal materials, and obtain a product design structure that fits the mold cavity. Production method.

Learn More

Sheet metal stamping parts are widely used in various industries, suitable for a variety of metal sheet materials, mainly including: carbon steel, stainless steel, cold rolled steel, aluminum alloy, copper alloy, galvanized steel, titanium alloy and so on. Sheet metal stamping does not change the properties of the material during processing. The material is changed into products of various shapes, sizes and properties through pressure, which is very suitable for the manufacture of large-scale sheet metal parts, with low cost, high efficiency and uniformity. gender and other characteristics.

Learn More

Stamping also called pressing involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Learn More

The process of turning sheets of metal into a useful part or component is called sheet metal stamping. The metal is fed into a press, where the stamping tool, also known as a die, creates the desired shape. The die is pressed into or through the metal with tremendous force. The force used in the process is measured in tons.

Learn More

Precision stamping parts are widely used, mainly including instrument and meter parts, IT parts, acoustic and camera parts, modern office parts, and daily hardware.These products usually have different functions in different fields.Generally, the thickness of the raw material can be processed from 0.05mm to 3.0mm. The raw materials are: beryllium copper (heat treatment required), phosphor copper, copper, brass, stainless steel, iron, aluminum, etc. In order to fulfill different mechanical function, stamping products can be conducted surface treatment. For example: electroplating, annodizing, passivation, heat treatment and so on.

Learn More

Heet metal stamping parts are metal components processed through stamping. This transformed sheet metals into durable stamped parts. During the process, sheet metals are formed according to your desired shapes.However, sheet metal stamping is done with a cold-forming technique. Unlike other sheet metal fabrication, even without using heat, components can appear hot due to friction produced between the die and metal. We also used materials such as stainless steel, aluminum, titanium, brass, copper, low/high carbon steel, and nickel alloys. All are strictly inspected before production begins.

Learn More

Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

Learn More

Sheet Metal Stamping is a low-cost high-speed manufacturing process that produces a high volume of identical metal components, which has contributed importantly to many industrial applications such as vehicles, equipment, electronics, appliances, tools, and so much more. For example, sheet Metal Stamping provides a large number of wholesale machine parts for Mechanical Industry.

Learn More

Sheet metal stamped parts are metal components processed through stamping. This transformed sheet metals into durable stamped parts. During the process, sheet metals are formed according to your desired shapes.For your stamped parts requirements, Our complete line of sheet metal stamping parts is a good choice for hardware, medical industry, automotive, renewable energy, residential improvement, industrial, aerospace, and more industries.

Learn More

Stamping consists on compressing a specific metal between two moulds. There are two types of stamping: the progressive stamping and printing by percussion. Sheet stamping metal get parts for a wide range of sectors: appliances, telecommunications, automotive, hardware, industrial machinery, home furnishings and furniture, electrical components….

Learn More

Stamping metal is a process that transforms flat metal into various shapes. The production method has benefits, including high precision, efficiency, cost efficiency, tight tolerance. Papler Industry offer clients customized solutions according to the metal stamping parts' size, complexity, and volume.

Learn More

From fuel delivery systems to airbag components, stamped metal parts can be found in almost every system of automotive vehicles. What unifies these disparate stamped metal parts in the automotive industry is the focus on quality - a quality that only metal stamping specialists like Papler Industry Co.,Ltd can ensure.

Learn More

Aluminum stamping is carried out in order to meet tough requirements regarding vehicle weight reduction. This technology is effective in addressing the impact on fuel consumption and the harmful greenhouse effects of carbon dioxide emissions.

Learn More

High precision metal stamping is a manufacturing process that utilizes a custom tool and die set installed in a stamping press to turn sheet metal into the desired components. It is used in a wide range of industries to create large quantities of parts and products with high precision, accuracy, and speed.

Learn More

Sheet metal stamping is a practical and effective way to meet the growing demand for fuel efficiency in the automotive industry. Sheet metal stamping can be used to manufacture a large part of an automobile's body including doors, hoods and trunk lids. The sheet metal stamping Processing strong auto body parts that help a vehicle meet fuel efficiency standards.

Learn More

Papler Industry Co.,Ltd extensive capabilities in Precision Metal Stamping often allow us to provide innovative solutions for our customers Metal Stamping requirements. We routinely provide consistent product for the most demanding applications. Our customers depend on us to provide Micro stamping products with ultra - tight tolerances, complex part geometries, specialty materials and in-die assembly operations.

Learn More

Papler Industry Co.,Ltd Custom Sheet Metal Stamping service provides metal stamping dies and techniques to produce parts specified by the customer. Papler Industry Co.,Ltd could offer a wide range of industrial and application parts and components that employ custom stamping die to meet high-volume production needs and ensure all parts meet exact specifications.

Learn More

Sheet Metal stamping is a cold-forming process that uses dies and stamping pressing machines to shape sheet metal into various forms. Pieces of flat sheet metal typically referred to as blanks, are fed into a sheet metal stamping press that uses a tool and dies surface to transform the metal into a new shape. The material is placed to be stamped between die sections, where the use of pressure will form and shear the material into the desired final shape for the product or component.

Learn More

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and progressive die stamping, to mention just a few. Parts use either a combination of these techniques or independently, depending on the piece’s complexity.

Learn More

Precision metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

Learn More

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shapes. It is a complex process that can include a number of metal forming techniques — blanking, punching, bending and piercing, to name a few, short run metal stamping、precision stamping、progressive metal stamping.

Learn More

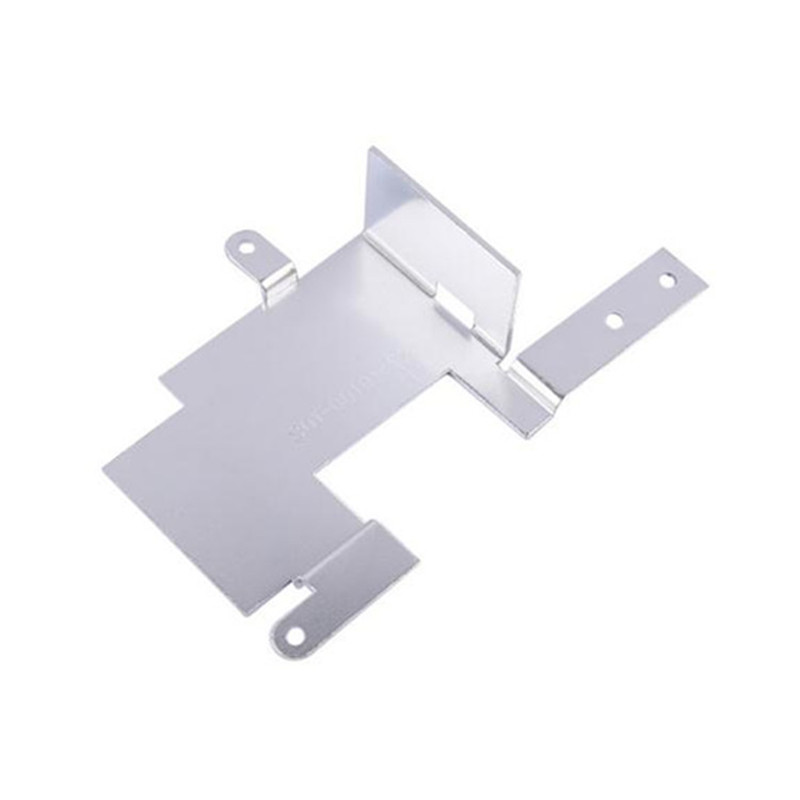

Metal stamping shim washers, often referred to as shims, are thin washers designed to stack under the head of a screw to create highly precise spacers in a number of applications. They are commonly used to ensure that a surface is level or to remove excess space to play within a mechanism,concentrate on various sheet metal parts.

Learn More

Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Learn More

Metal stamping is a complex process that can include a number of metal parts stamping forming processes —blanking, punching, bending, and piercing and more.

Learn More

Metal stamping is a manufacturing process used to convert flat metal sheets into specific shape stamping sheet metal parts. It is a complex process that can include a number of metal forming techniques - blanking, punching, bending and piercing.

Learn More

Sheet metal enclosures are designed to hold or protect other items or equipment, and they all require the expertise of a precision sheet metal fabricator to be manufactured correctly. This is especially true for enclosures intended for use in highly - regulated industries, such as medical, energy, food service, military, or aerospace.

Learn More

As leaders in metal stamping, our custom stamping metal parts produces a variety of components. Our customers rely on our expert design and development services. We create a range of metal components in all sizes, from simple to intricate. We provide service and support to our customers throughout the entire process, from prototype development through high-volume production. We have the capability to process orders of up to 50 million parts.

Learn More

Metal stamping is a manufacturing process in which coils or flat sheets of material are formed into specific shapes. Stamping encompasses multiple forming techniques such as blanking, punching, embossing, and deep draw metal stamping, to mention just a few.

Learn More

Stamping die manufacturing process, blank coils or sheets get fed into a stamping press which uses tools and dies to form features and surfaces in the metal.

Learn More

Metal stamping part is an excellent way to mass-produce various complex parts, from car door panels and gears to small electrical components used in phones and computers. Stamping processes are highly-adopted in automotive, industrial, lighting, medical, and other industries.

Learn More Contact Us

Contact Us Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China

Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China WhatsApp : +86 18259211580

WhatsApp : +86 18259211580 Email : roger@ppl2009.com

Email : roger@ppl2009.com IPv6 network supported

IPv6 network supported