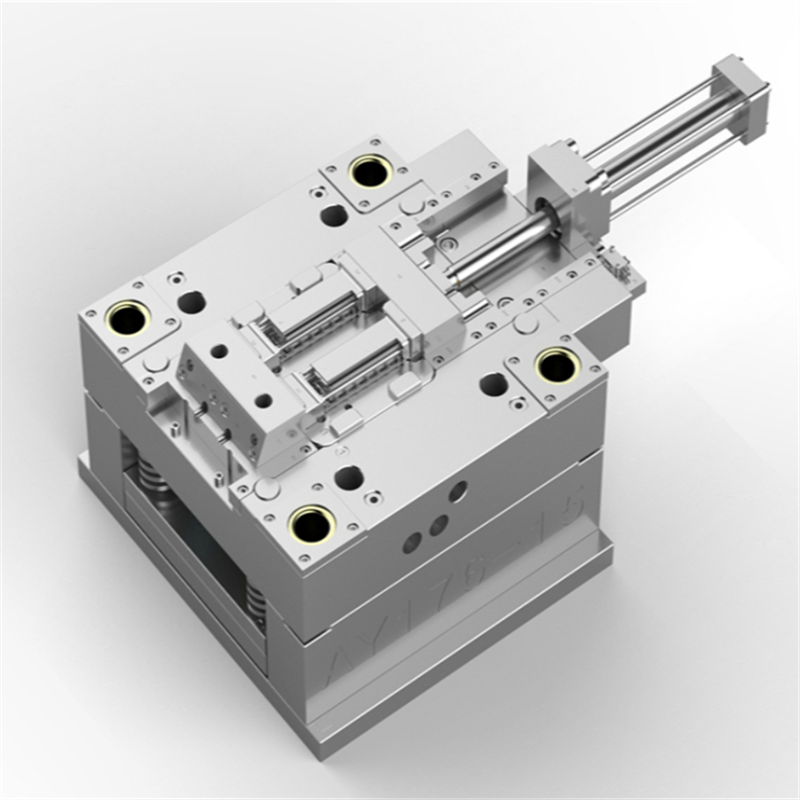

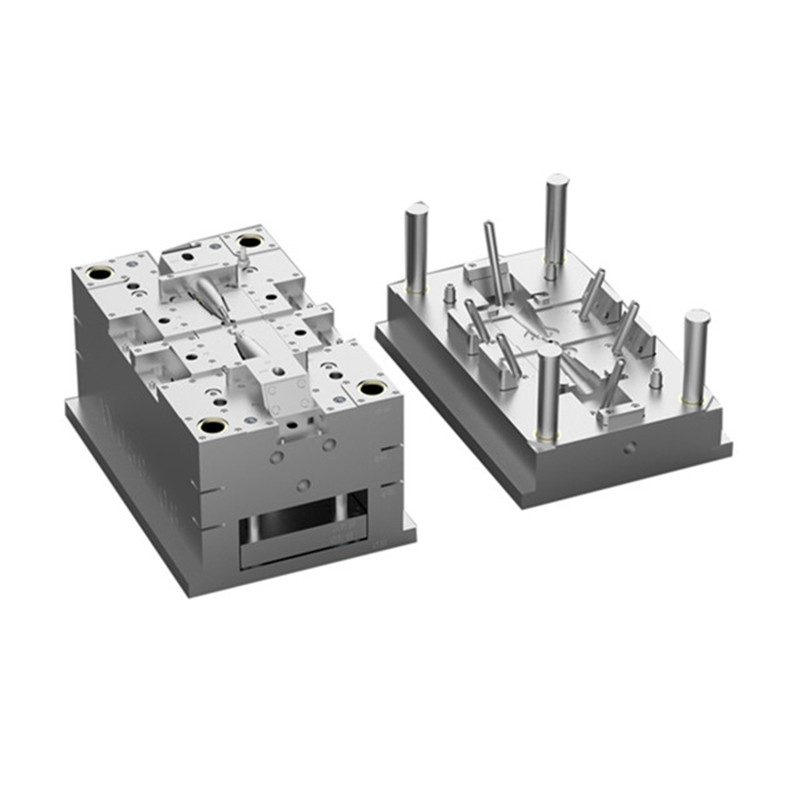

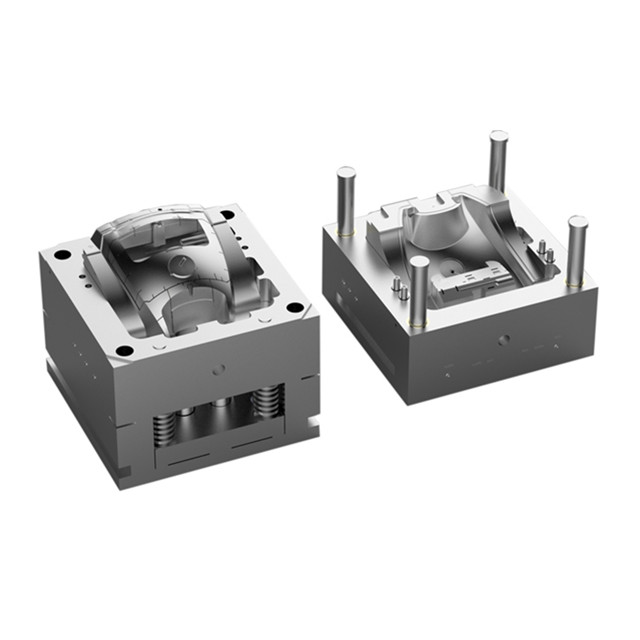

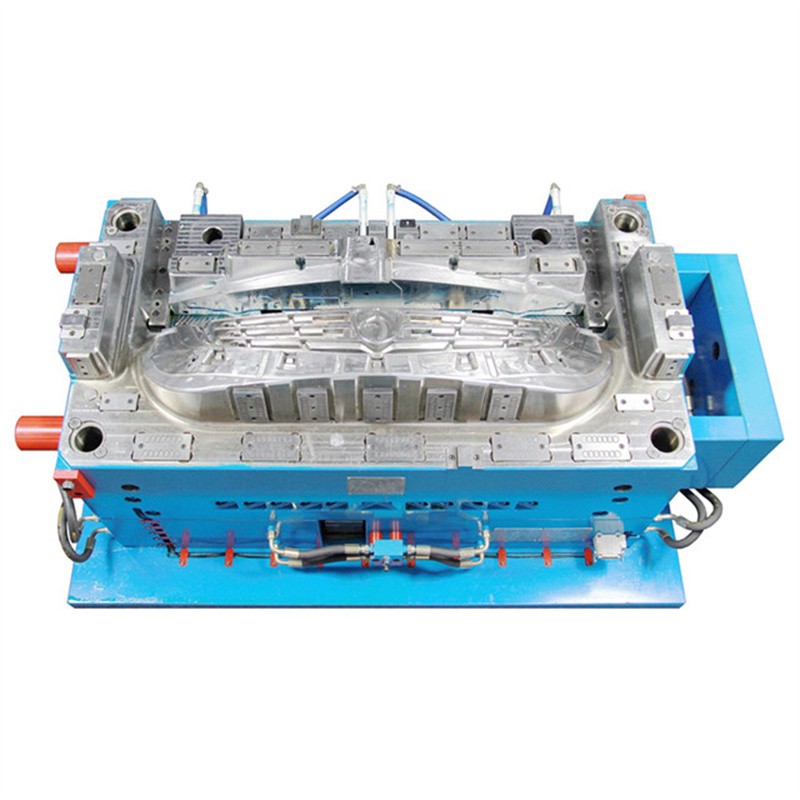

A mold is a special injection molding tool. Custom molded component manufacturers design and fabricate the mold specifically for the part they'll produce. When the production run for a part is finished, specialists replace the mold with a new mold for the next part they need to manufacture.

Plastic Injection Molded Parts

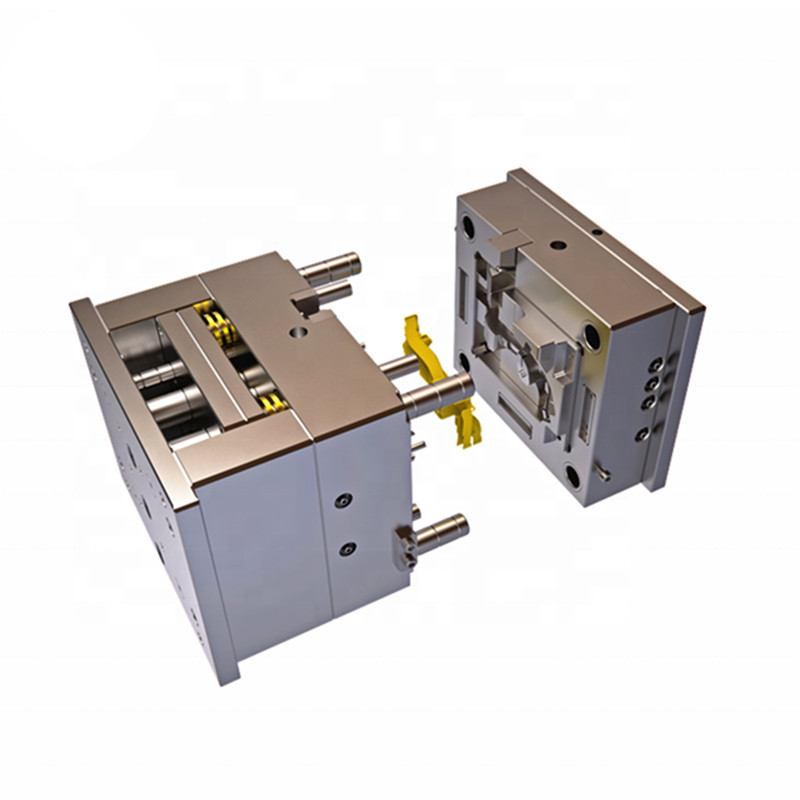

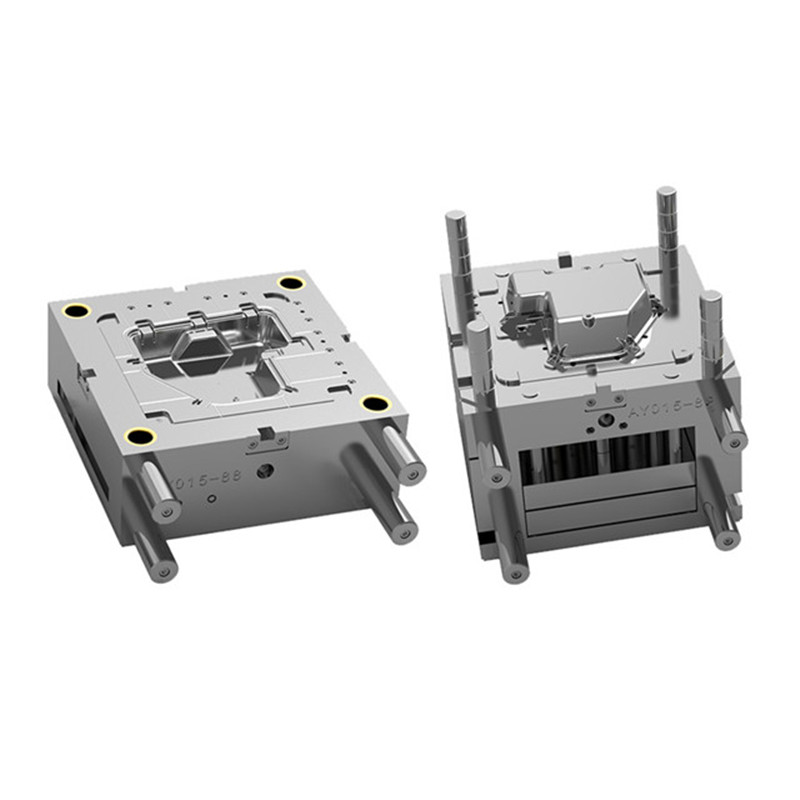

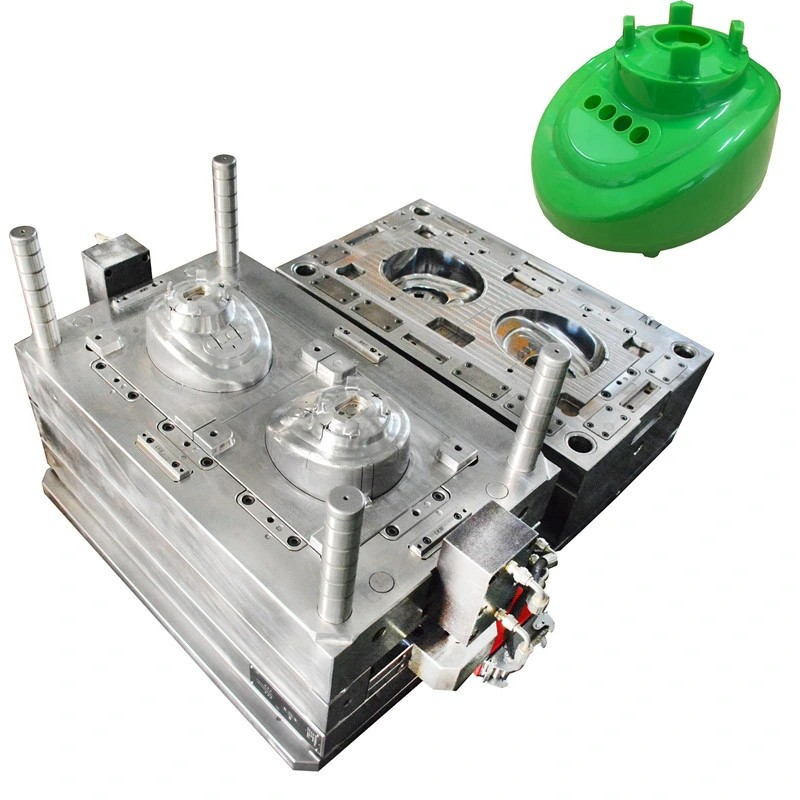

Injection molding is a process in which custom molded component manufacturers heat a polymer until it reaches a highly plastic state and forces it to flow under high pressure into a mold’s cavity to solidify. Manufacturers then remove the molded part, or molding, from the cavity. The process produces discrete components that are almost always net shape, reducing the need for surface finishing. A mold may contain more than one cavity, allowing custom injection molding companies to produce multiple moldings each cycle.

Variables that Impact the Injection Mold Cost

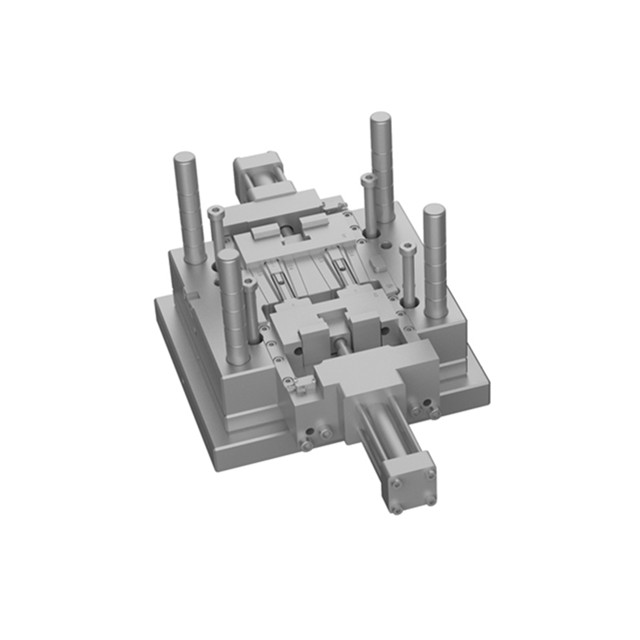

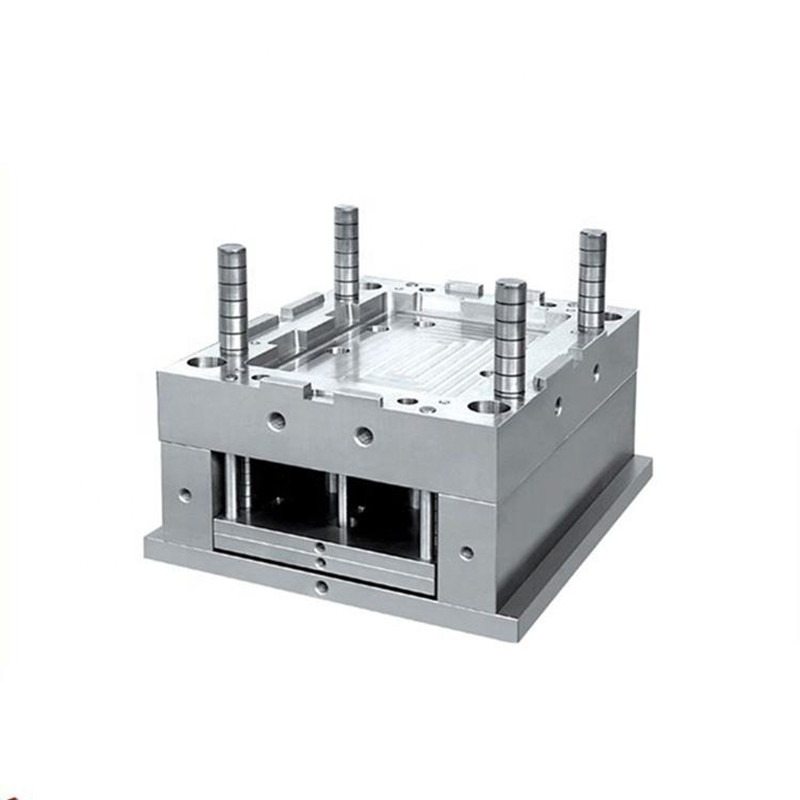

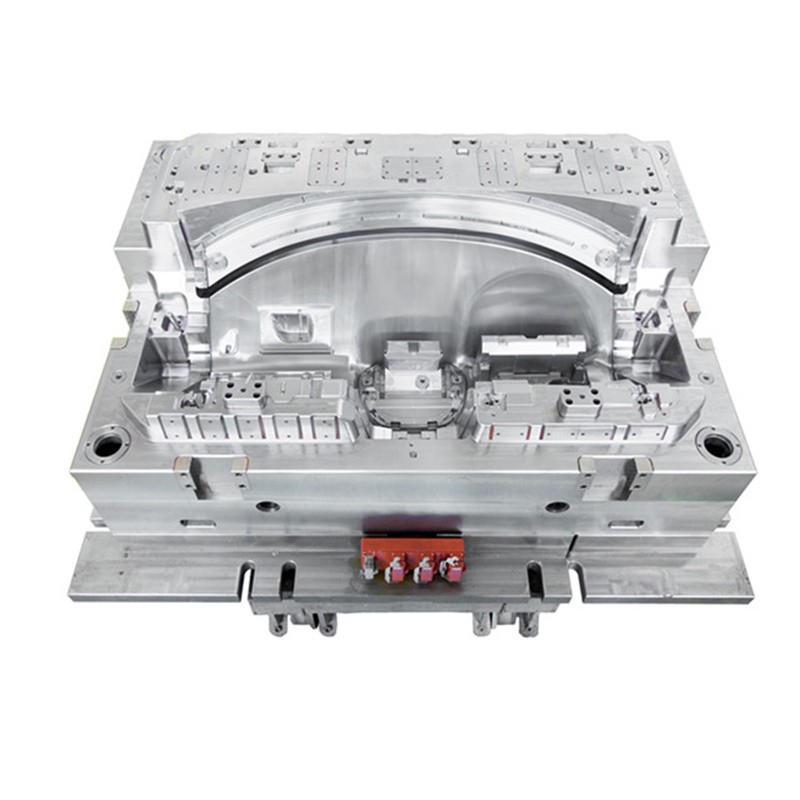

Tooling costs for injection molding are very high and depend on a number of parameters and design complexity. Molds for injection molding are normally CNC machined out of aluminum or tool steel, EDM machined to shape a workpiece, or 3D printed. The machined or printed part is then finished to achieve the desired standard. The finished mold consists of features such as the surface geometries needed for a part, a runner system to guide the flow of injected materials, and cooling channels to ensure the mold cools down quickly. It is important to note that a majority of the injection molding process is dedicated to cooling. The quicker a mold cools down the faster the injected material solidifies and the faster the production cycle can be repeated. Thus, cooling channels play an important role, especially for high-volume production, and should be included in the design of the mold. For low-volume production with 3D printed injection mold, manual cooling using compressed air is an option.

Papler Industry are an experienced injection mold manufacturer. We have built many tools over the years and can offer you solutions in each area. We can offer our new Laserstar Laser Welding system to help with all your repair or engineering changes. Contact us for a quote on your project.

Learn More

Injection molding is a popular manufacturing process for producing large quantities of plastic parts from materials called thermoplastics. It's the process of melting plastic, injecting it into a mold then repeating the process to make thousands or even millions of the same part.

Learn More

Custom plastic injection molding is ideal for plastic parts where success relies on achieving specific mechanical or aesthetic features. No stranger to complexity, design challenges really stoke our desire to innovate for you.

Learn More

A mold is a special injection molding tool. Custom molded component manufacturers design and fabricate the mold specifically for the part they'll produce. When the production run for a part is finished, specialists replace the mold with a new mold for the next part they need to manufacture.

Learn More

ABS plastics are thermoplastics and have applications in many industries requiring strong and impact-resistant materials manufacturing. As a thermoplastic material, ABS does not burn upon heating. Instead, it becomes liquid during the ABS molding process to ensure easy injection molding and recycling.

Learn More

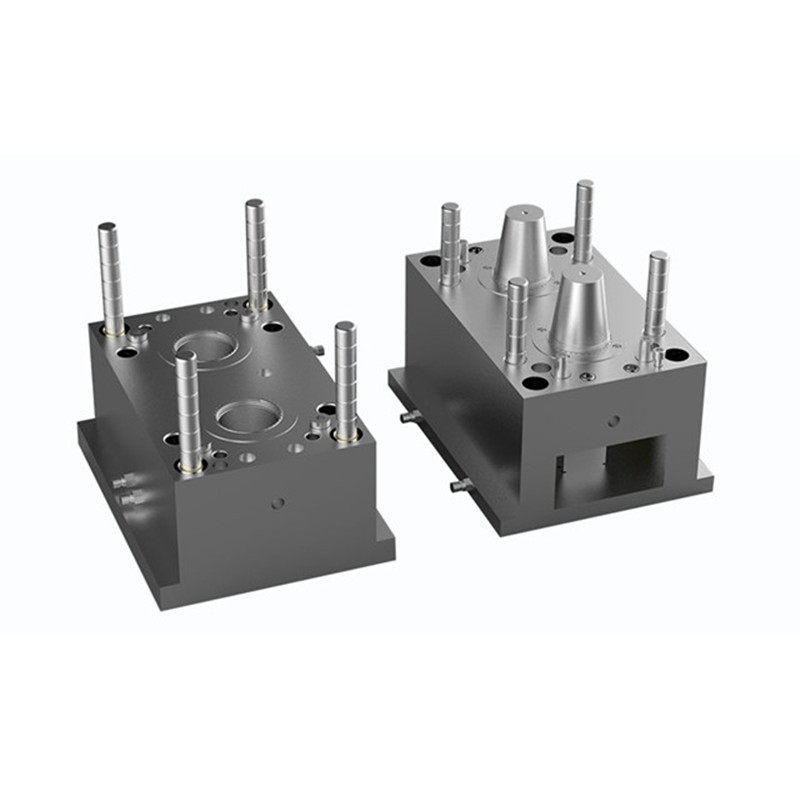

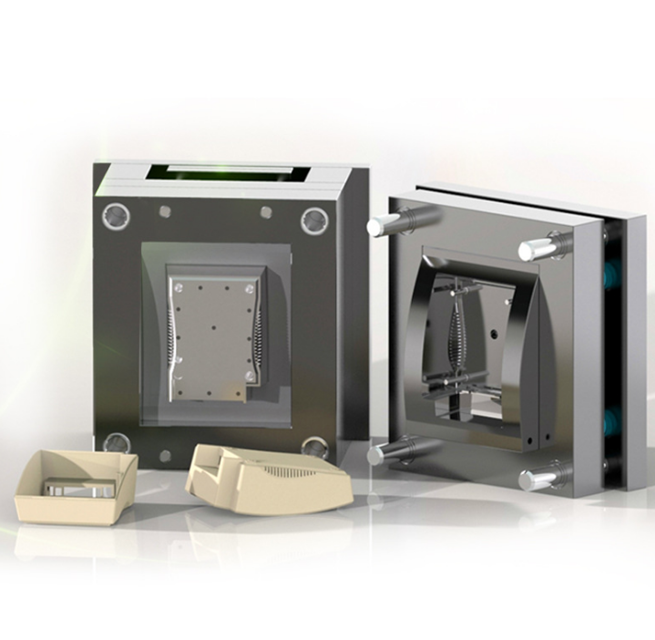

The core & cavity design of the plastic injection mold tooling is what gives the final product its shape, but there are several other functions of the tool that are crucial for the correct formation of the end product. The tool places a large role in the correct cooling down rate of the moulded plastic part. If a plastic material sets at the wrong speed, distortion and stress may occur. The material of the tool should be chosen to keep cooling down rate in mind. Some plastic materials may need to be moulded in a water cooled tool.

Learn More

Papler Industry is an injection mold manufacturer based in China. With our in-house precision manufacturing equipment, we areable to offer multiple services: product design, mold design,mold making and injection molding.

Learn More

Molding plastic injection is the process of pushing or injecting molten plastic into a mold cavity. Plastic resin is fed into a heated barrel, mixed, and injected into a tool, where it cools and hardens to the configuration of the mold cavity. Papler Industry Co.,Ltd molding process is ideal for high or low production runs and can handle the challenges of complex geometries.

Learn More

High precision molds for the replication of structured optical elements like Fresnel lenses or prism arrays are generated by diamond machining or precision grinding. In some cases surface quality of the replicated components is not sufficient to meet the increasing demands concerning surface roughness and form accuracy for optical applications. Subsequent polishing of the structures may therefore be necessary. Within this work structured molds were finished by a newly developed abrasive polishing process, by laser polishing, and by abrasive flow machining. This paper focuses on the material removal mechanisms and achievable surface quality in abrasive polishing. Surface quality is compared to that achieved by laser polishing and abrasive flow machining.

Learn More

Prototype plastic injection molds produce real injection molded parts for functional testing. They can also serve as bridge tooling to fill the manufacturing gap for production tooling. Prototype molding is built quickly; the part has the shape and functionality a plastic prototype part would need for testing form, fit and function, but may not have fine details like color preference or surface finish. Prototype molds are warrantied for up to 10,000 cycles.

Learn More

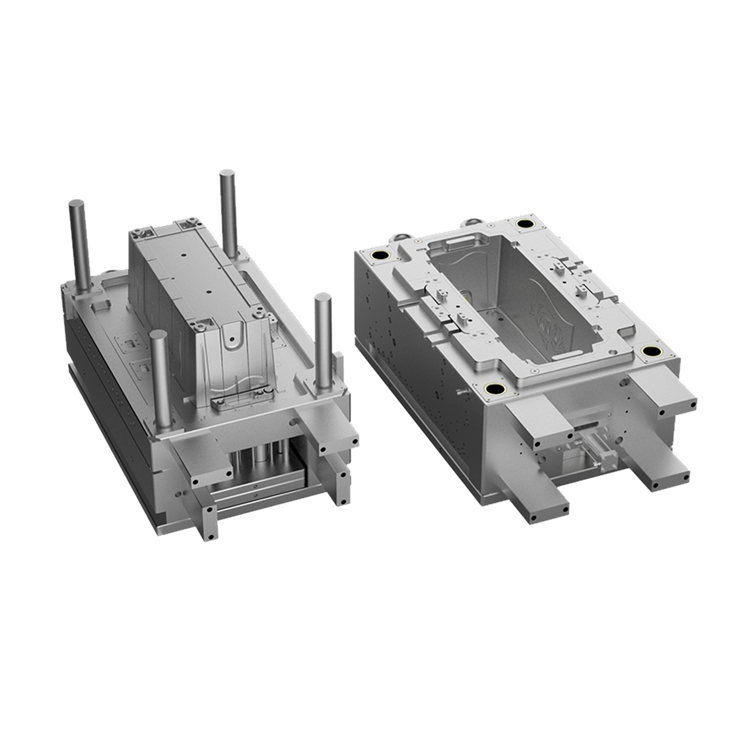

A precision injection mold has dimensional tolerances controlled below 1/3 of the dimensional tolerance of products. The precision of the mold depends on the precision of the cavity size and number of cavities in the design, positioning of the cavity, precision of the parting surface, material selection, and dimensional tolerance. The thickness of the bottom plate, supporting plate, and cavity wall as well as the runner size are all important factors of the precision mold. Design engineering is equally important. The mold is usually made of alloy steel, which has high mechanical strength.

Learn More

Papler Industry Co.,Ltd utilise a rapid injection moulding a technology-driven process that leverages manufacturing automation. CAD models are sent directly to the production floor where mould milling begins, but in most cases, moulds are fabricated from aluminium, not steel. This allows for faster and most cost-effective tooling when compared to traditional steel moulds.

Learn More

Mold design is a basic but important part in injection molding, regardless of the size and position of the gate, the size of the shear edge, flow assist, cooling and ejector technology, all affect the final mold injection results. It is no exaggeration to say that mold design has a significant impact on the cost-effectiveness and quality of molded parts and your products.

Learn More

Precision molding is the latest technology in the world of plastic injection molding. Precision molding is a type of plastics molding that is the most expensive and sophisticated process of mold design in the market.

Learn More

Precision injection molding is a process that requires high technique and the use of precision molds and precision machines. The process of precision mould is different from normal injection mold but it still belongs to injection mold. It requires strict tolerance of ±0.01 mm and it will be processed by high precision machine and technique. It has strict requirements for venting, material flowing, and cooling which enable molding parameters to be stable.

Learn More

Molds themselves have to be constructed so that the various parts can be fitted, the air escape as the material is injected and then a coolant allowed to flow through to bet the entire mold down to a temperature to cool the product efficiently so that it hardens sufficiently to be removed and stay in shape. Thus once a mold is made the limitations are the injection and the cooling as to the number of products that can be produced. Obviously the unit cost per product is massively reduced the longer the run as molds may wear over time but usually will last for long runs of many tens of thousands of products before needing maintenance.

Learn More

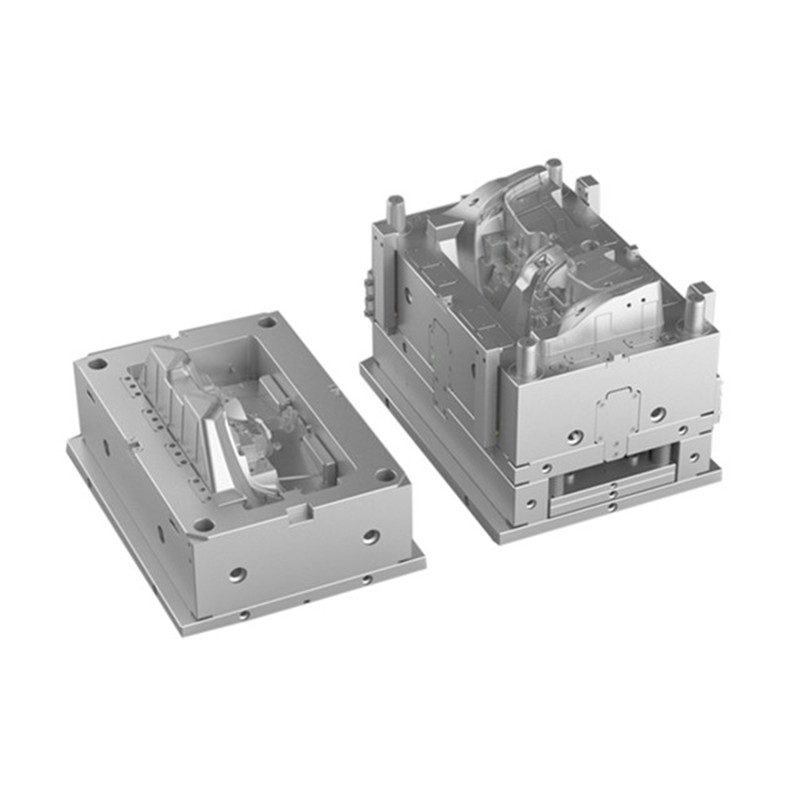

To achieve the goal of minimizing costs in the process of producing automotive stamping mold, optimization and improvement need to be carried out from the preliminary design, production and manufacturing process, and post-production comprehensive performance debugging. In the automobile production and manufacturing industry, reducing the cost of automobile stamping dies in the production and manufacturing can keep the company competitive in the market and not be eliminated by the times.

Learn More

Papler Industry Co.,Ltd have extensive experience in plastic inject mold design and injection molding interior and exterior plastic car parts. Our staff is well-trained in specialized techniques like insert molding and overmoulding which are essential in manufacturing plastic car parts with a strong durable structure. We also use premium plastic materials and cutting-edge technology to produce each part with flawless precision.

Learn More

Injection molding is the process of making custom plastic parts by injecting molten plastic material at high pressure into a metal mold. Just like other forms of plastic molding, after the molten plastic is injected into the mold, the mold is cooled and opened to reveal a solid plastic part. The process is similar to a Jello mold which is filled then cooled to create the final product.This mold can help you improve production schedule and increase production capacity.

Learn More

Our rich experience as a China plastic injection molding company includes production capabilities for many different industries, plastic materials, and specialty add-ons for your custom plastic parts. Our focus is on production runs of 100 to 100,000 units per order. We know every custom injection molding project is different, but every customer enjoys our key values: High quality custom plastic injection molds and custom parts with reliable on-time deliveries Outstanding attention to customer needs through advanced quality planning Fast quotes and delay free communication Friendly and knowledgeable customer service

Learn More

Whether you manufacture computer components, sporting goods equipment or automotive interiors, you are likely familiar with plastic injection molding. When your products call for plastic parts, plastic injection molds from plastic injection molding companies who specialize in this process provides the most efficient, one-step solution. Plastic injection molding companies are not all created equally. Quality products and superior customer service are leading business values for Papler Industry. We believe responding to our customer’s needs with cost-efficient, innovative solutions and expert support services is a win-win prospect.

Learn More

Our experience, coupled with the latest technology and equipment, enables Papler Industry to produce the superior-quality molds and molded parts our customers and their clients count on. As a professional plastic mold manufacturer in China, some of the services we provide in addition to plastic injection molding includes custom injection molding, prototype injection molding, insert molding, and more.

Learn More

Metal injection molds, also called dies, are used to produce a vast range of injected plastic products across every industry. Other companies may sub-contract their mold construction. Papler Industry’s plastic injection molds are all manufactured in-house from our dedicated mold-build facility in Michigan. Constructing the molds is the most time-consuming phase of the injection molding process. They require precision tooling by skilled technicians. Our experienced toolmakers work alongside our engineers and inspectors throughout the construction process to ensure everything is built exactly to specification. This level of attention is required because even the smallest misstep can cause costly errors.

Learn More

When researching plastic injection molding companies, it is important to know their mold-construction philosophy and warranty options. Once you have invested in a top-quality injection mold, you will have a durable, precision product that can be used over and over, run after run. Our plastic injection molding company’s mold builds carry an unlimited tooling warranty, good for as long as we are running your production parts.

Learn More Contact Us

Contact Us Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China

Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China WhatsApp : +86 18259211580

WhatsApp : +86 18259211580 Email : roger@ppl2009.com

Email : roger@ppl2009.com IPv6 network supported

IPv6 network supported