CNC milling service can rapid machining of various parts while minimizing human intervention for process planning. Using layer-based methods such as traditional rapid prototyping, rapid, semi-automatic machining of common fabrication part geometry in a variety of materials. Machining parts from directions about the axis of rotation using multiple 21/2-D tool paths.

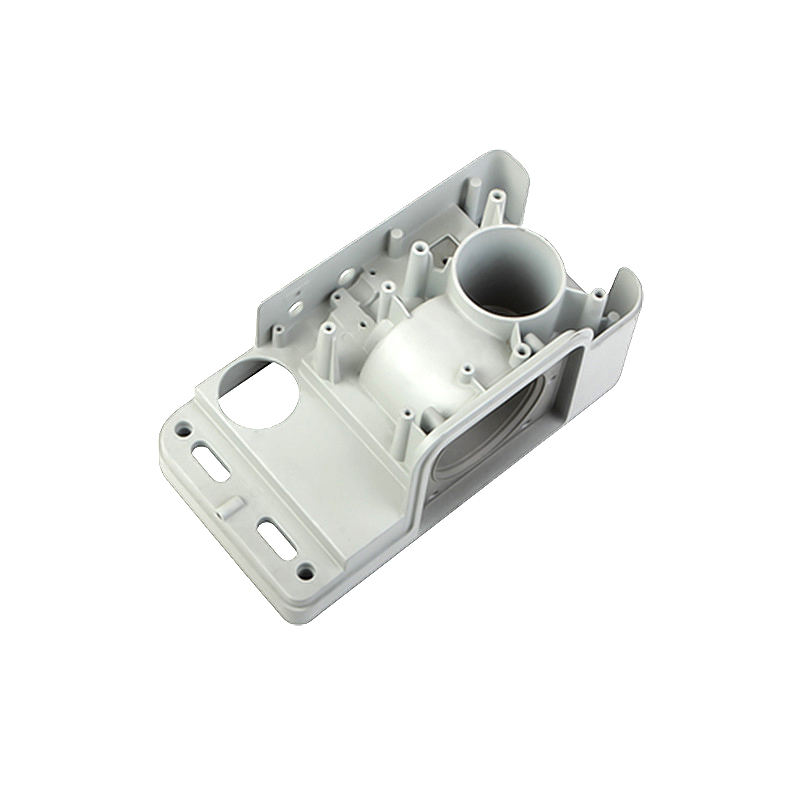

Best CNC Milling Service for Precision Flange CNC Milling Parts With a Competetive Price

CNC Milling Service

Papler industry is a professional online parts manufacturing company that provide precision CNC milling service with advanced milling centers from 3-, 4-, to 5- axis, we offer global custom CNC machining parts online for various industries demand. Our precision CNC milling machine and 20+ Years experienced team guarantee our advanced CNC milling parts quality, we can handle all your CNC milling projects smoothly from design, prototyping, producing to final transportation.

What is CNC Milling?

CNC Milling is the process of cutting and drilling material (like plastic or metal). A milling machine, regardless of whether it’s operated manually or through CNC, uses a rotating cylindrical tool called a milling cutter. It is held in a spindle and can vary in form and size. The main difference between a milling machine and any other drilling machine is the ability to cut at different angles and move along different axes. Various complex parts can be processed quickly.

How is the CNC Milling Work?

CNC milling is a subtractive manufacturing process. It starts by fixturing a block of metal or plastic materials inside the CNC milling machine. The CNC milling machine will transfer the CAD model file into CNC readable program–G code, which is used to program the CNC machine rapidly mill our parts from raw material blocks. Our best 3-, 4- and 5-axis CNC milling machines are equipped with different tool-sets to maximize production efficiency and speed.

What Materials Can be Milled?

We work with a wide range of plastic and metal alloy materials including magnesium, mild and stainless steel, aluminum, brass, and titanium as well as rigid engineering grade plastic resins. These materials are part of our standard inventory and can be sourced for immediate availability from reliable vendors who have been thoroughly vetted and approved by us. In addition, we can also provide specialty materials such as super hard alloys – just talk with our engineers to learn how we can meet your needs.

Most importantly, to ensure that your CNC machined parts meet all regulatory requirements we have an incoming materials inspection lab where we use sophisticated analytic testing instruments using Raman spectroscopy to confirm the exact chemical and physical properties of all raw materials. We leave nothing to chance for your peace of mind.

Industrial Applications of precision CNC Milling Parts

The shapes that can be made by CNC Milling include various flat surfaces, tapers, contours, fillet and radius contours, and threaded surfaces. Although many turned parts use a single axis of rotation, there can also be multiple axes to provide greater flexibility (for example, camshafts).

—Automotive industry:

engine, housing, screws, motor shafts, bearing sleeves, knobs, gaskets, shift levers, hydraulic valves, valve housings, sensor housings

—Machinery industry:

fasteners, bushings, screws (rivets, bolts, nuts), shafts, engine components

—Medical and biotechnology:

medical speculums, auxiliary surgical instruments, optoelectronic instrument components

—Electronic products:

PCB auxiliary board, light-receiving end interface ferrule assembly, optical device metal assembly, product metal shell

The two main types of CNC (computer numerical control) machining systems are milling and turning . Due to the characteristics of each machine type, milling and turning are each uniquely ideal for manufacturing different geometries.

Learn More

We have everything needed to produce the best custom-made steel metal CNC machining parts for our diverse customer base. With a wide variety of milling capabilities, we have the expertise to tackle any project and meet exact specifications. Our CNC machining services include CNC milling machining that is ideally suited for producing intricate parts where precision and accuracy are of the utmost importance. Our CNC machining parts capabilities range from very small to large capacities. And, when you choose us for your CNC milling machining needs, you’re assured of receiving a finished product that will exceed your high standards in terms of quality, accuracy, and precision.

Learn More

We operate different kind of CNC mill and turning center, and on being able to machine whatever you need, from simple, 'as-machined' workholdings to complex, organic geometries with tight tolerances.

Learn More

The die casting process involves injecting molten metal with low melting points such as zinc and aluminum into the die casting mold and allowing it to cool. Depending on the melting point, it occurs under two different mechanisms (hot and cold chamber casting), and it is suitable for making simple and complex sheet metal parts.

Learn More

With the development of CNC machining, manufacturers have completed complex processes easily and efficiently. One of the process’s applications is in making prototypes, CNC prototype machining is one of the best.We have invested heavily in our CNC machining department in terms of machinery and staff, enabling us to fulfil orders quickly. Find out more about our CNC milling and CNC turning capability.

Learn More

Die casting is a process that involves melting low melting point metals and injecting them into already made mold known as die casting mold. A mold or tools come from steel fabricated for a single project using manufacturing processes such as CNC machining. Consequently, sheet metal parts fabricated by die casting have high accuracy, precision, and repeatability.

Learn More

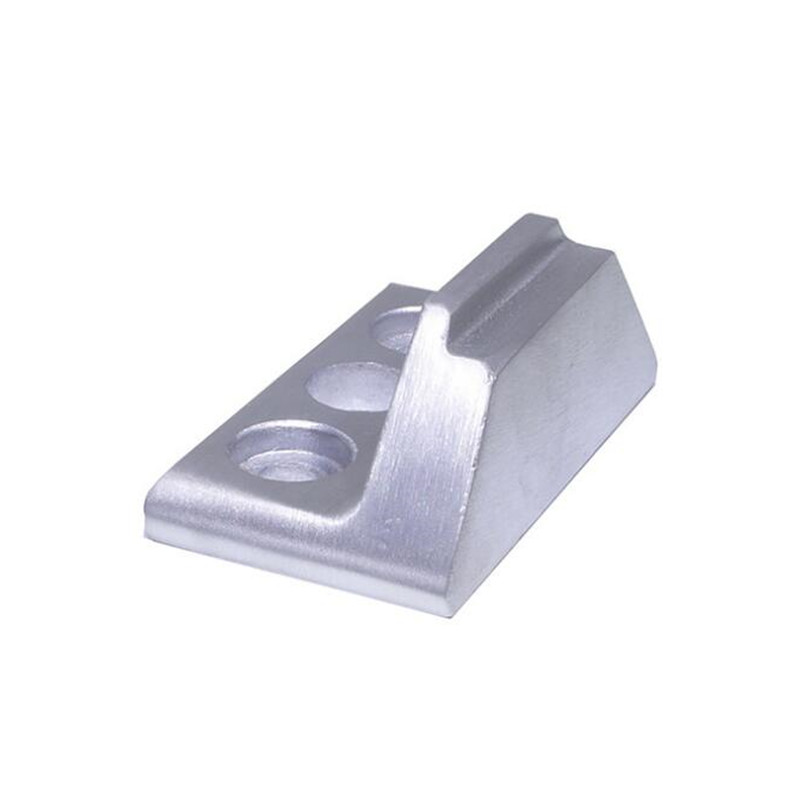

We hold specialization in providing customers with a variety of non-standard brass CNC turned components. These products are manufactured with high quality raw materials and advanced technical machines. Corrosion resistant Superior finish Low tolerance

Learn More

Rapid prototyping CNC machining is a process used in producing one sample or a small batch CNC machining trial production of a product before its mass production and manufacturing. The process of CNC prototype is ideal for various things. For example, Prototype CNC machining service is suitable for obtaining a sample of the product you want to develop at a lower cost.

Learn More

For precision CNC machining parts including CNC turning parts and CNC milling parts, we have full experience to provide you with professional solutions. A wide variety of materials can be machined, including stainless steel, aluminum, cooper, bronze,zinc, brass and much more. Welcome to get your quotation!

Learn More

Prototype CNC machining exponential control machine is programmed and controlled by CNC machining language. CNC machining has a lot of things compared with manual machining, such as CNC machining parts are very accurate and reproducible; precision cnc lathe machining service can produce parts with complex shapes that cannot be completed by manual machining.

Learn More

CNC precision machining is a traditional process in which excess material is cut off by elimination. CNC processing speed, low cost, processing materials with high strength, high temperature resistance, high toughness, transparency and other requirements; And CNC model processing forms are not limited to one style, such as polishing, ash spraying, painting, polishing, screen printing, UV, electroplating, etc. (especially the model that needs electroplating), its effect can be completely comparable to the product produced by the mold, or even higher; In appearance, assembly, functional verification can achieve the customer's final design intention.

Learn More

We're specialized in CNC machining custom/milling/turning, with many years experience in machining industry. Our objective is to develop and produce products to meet your exact specifications, in the meanwhile, offer reasonable prices and professional services to satisfy your expectations and budget.

Learn More

CNC machining is a general manufacturing process, suitable for a variety of materials. However, in product manufacturing, the process is more common to use aluminum, that is, machining aluminum. Aluminium alloy processing is a process that involves the use of aluminium in the manufacture of products because there are many grades of aluminium. Aluminum is highly machinable and relatively inexpensive, and different types of aluminum alloys are suitable for a myriad of processing applications. This includes rigid building components, aerospace parts manufacturing, etc.

Learn More

We offer a variety of stainless steel options to suit any specifications or requirements. Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. If you need CNC machining stainless steel please be sure to contact us, as it is likely that we can provide it for you.

Learn More

CNC milling service can rapid machining of various parts while minimizing human intervention for process planning. Using layer-based methods such as traditional rapid prototyping, rapid, semi-automatic machining of common fabrication part geometry in a variety of materials. Machining parts from directions about the axis of rotation using multiple 21/2-D tool paths.

Learn More

We specialize in precision machining using our state-of-the-art equipment. Our expertise and experience leave us especially well-prepared to manufacture small and complex parts. Request a quote today to see how our precision machining capabilities can serve your project, or contact us with any questions you may have.

Learn More

CNC turning machining is the go-to choice if you are producing a part with cylindrical feature, and it can produce complex components of varying sizes and shapes according to your specifications. Wenext's wide range of CNC lathes, advanced quality assurance system, together with our highly experienced team of professionals, are ready to take on all kinds challenging machining jobs for you.

Learn More

CNC machining is a broad parts manufacturing category that includes many different computer-controlled processes where raw material is selectively removed in exact amounts to produce a near-final shape of parts. That’s why it’s considered subtractive, as opposed to additive manufacturing or 3D printing. Standard CNC machining processes include CNC milling, CNC turning, surface grinding, and electrical discharge machining (EDM) although there are other specialized applications. Whenever a machine is digitally controlled there must always be a 3D CAD file of the part design which is used to program the machine’s movements.

Learn More

From 1 to 10,000 pieces, our CNC machine shop carries a huge selection of cnc machining car parts that meet your exact needs for automotive or other products. When you need to deliver your custom parts on a short timeline, there are no limitations to what we can produce.

Learn More

Computer numerical control (CNC) are automatic three-dimensional cutting and milling machines that, compared to other cutting methods, minimize material waste and reduce errors. These machines come in many configurations, ranging from small DIY desktop CNC mill aluminum routers to industrial equipment used in manufacturing plants.

Learn More

CNC machining parts manufacturer with CNC Lathes and CNC turning centers, providing cost-effective precision machining services with fast lead times. Live tooling available for complex projects.

Learn More

CNC is the abbreviation of "computer numerical control", cnc service machining is a kind of manufacturing process that instructs the operation of equipment and tools through programmed computer. This process can control various complicated machinery, such as CNC milling machine, CNC lathe, CNC laser machine, water jet machine, electric discharge machine (EDM), to complete the three-dimensional cutting task.

Learn More

We offer a complete CNC aluminum machining service and can produce complex aluminum parts with 13 different types of aluminum. Aluminum parts are great for applications that require high strength, corrosion resistance, heat tolerance, low weight, electrical conductivity, and overall versatility.

Learn More

Our company guarantees that your CNC machined aluminum parts will be manufactured according to your drawing specifications. Our engineers will be happy to help you optimize your design to make your products cost effective, while our machine operators will ensure 100% quality of each aluminum part manufactured on a CNC car milling machine.

Learn More

Our experienced CNC machining engineers can select the right tools and optimize tool paths, achieve an ideal CNC milling surface, and keep tight tolerances. We can provide all types of custom CNC machining parts to meet your project needs.

Learn More

Precision CNC machining works with a variety of materials including metals, woods, acrylics, foams, and thermoplastics. Contact us to learn more about our CNC precision machining services and how we can help you with your production requirements.

Learn More

Our offers a truly unparalleled level of expertise in custom brass machining. We work with both free machining and Naval brass and offer numerous plating options, including electroless nickel plating, which adds a less porous, all-enveloping barrier to CNC brass parts for superior corrosion resistance.

Learn More

We specialize in machining complex plastic and composite parts. Our CNC plastics machining are used for a variety of industries, from aerospace to electronics to commercial applications. Our engineers are experts in plastics and will work with you to create the highest quality parts that meet your exact needs.

Learn More

The systems used in CNC milling operations are known as CNC milling machines. They can have a moving workpiece and a stationary rotary tool, a stationary workpiece and a moving rotary tool, or a moving workpiece and rotary tool, depending on their design and the milling requirements. As CNC milling generally serves as a secondary or finishing process for machined components, milling machines can be used to create design elements such as flat surfaces, contours, grooves, slots, notches, holes, and pockets.

Learn More

Our advanced CNC metal machining lathes and rich experienced workers and engineers could help you save a lot of purchasing costs. Can guarantee the aluminum alloys will be the exact material that you need for your project and can ensure the right tolerances according to your needs.

Learn More

CNC machining is versatile for producing prototype parts in metals, alloys and engineering plastics. Quick and cost-effective, CNC (computer numerical controlled) machining is more accurate than 3D printing parts, so is excellent for functional prototypes. Typically, we CNC machining parts that will be manufactured by other processes once they are in mass - production. In addition, we CNC machine one - off final parts and small batches for special-purpose machine builders and manufacturers of low-volume, high - value products.

Learn More

Anodizing is a key step in manufacturing aluminum CNC machined parts. An electrochemical process that involves coating a metal part with an oxide surface layer, anodizing gives the part additional sturdiness and a more attractive finish. Anodizing ensures a part can resist corrosion and wear and tear from prolonged use, and that it retains its cosmetic appearance under any conditions.

Learn More

For complex and time - sensitive machined parts, 5 - axis CNC machining machine offer unparalleled flexibility and speed. Papler Industry Co.,Ltd experienced team can help bring your ideas to life, from rapid prototypes to end - use parts for safety - critical applications. Our 4 - axis, 5 - axis milling capabilities enable us to provide precise parts with complex geometry.

Learn More

Papler Indusrtry provides a complete CNC machining service. From technical drawings, CNC bar turning, inspection and quality assurance to cleaning, surface and heat treatment. Our dedication to quality and customer service means we can deliver small to large series of parts ready for immediate use.

Learn More

Benefits of CNC machining Highly accurate parts with tight tolerances Excellent material properties Quick turnaround times One-off custom parts & prototypes Small-to-medium production

Learn More

CNC machining has many applications in the electrical and electronic manufacturing industry: from the prototyping of PCBs to the manufacturing of enclosures. for example, used CNC machining to manufacture an enclosure for their high-power electronic sensing systems. Heat dissipation and electrical insulation were the main design requirements in this case. So, CNC machined anodized aluminum was ideal for their one-off custom enclosure.

Learn More

CNC machine operators work in a wide variety of fields. People from all different pursuits, such as hobbyists and even military groups, take advantage of the cost savings accrued by using CNC machines to turn raw materials into final products. The machines are faster, more efficient and safer, too.

Learn More

Are you looking for a reliable and quick-turn provider of CNC machining services? You’ve come to the right place! Using state-of-the-art CNC technologies, our unmatched team of machinists, engineers, and quality control experts works together to ensure your products are done right and shipped on time. Our CNC machining services also complement our other manufacturing capabilities (like 3D printing and injection molding), providing you with an all-encompassing manufacturing solution. We produce simple and complex precision machined parts in a broad range of materials and surface finishes.

Learn More

CNC machining is a manufacturing process that uses computers to automate various machine tools. The CNC machining process typically begins with a computer aided design (CAD) program, which can be used to create specifications for a component, part, or other manufactured product. This design is then turned into a series of numerical values that a CNC machine may use to move and operate a variety of tools. A part may be completed in one CNC machine or it may be moved manually or through robotic means between several workstations with different tools.

Learn More

CNC is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to remove layers from a solid block of material. The desired cuts in the metal are programmed according to corresponding tools and machinery, which perform the machining task in an automated fashion.

Learn More

The primary advantages of CNC machining include rapid prototyping and the ability to produce full-scale production parts quickly. It offers a high level of precision and accuracy in manufacturing parts and allows for tight tolerance machining for CNC parts of all sizes. It also offers maximum flexibility across volume, pricing, lead times, and the range of materials and finishes being used.

Learn More

Industries that use CNC machining include aerospace, automotive parts manufacturing, medical machine manufacturing, transportation, defense, and marine industries, along with oil and gas industries and electronics. CNC machining has allowed these industries to become more efficient at mass-producing custom CNC parts.

Learn More

CNC machining is a subtractive manufacturing process in that it involves using cutting tools to remove material as needed to form the desired part. This approach contrasts with an additive manufacturing technology, also called 3D printing, in which material is added layer-by-layer to build up a part to its desired final form as opposed to removing material from a blank to generate it.

Learn More

As electronics and semiconductor technology evolved and advanced, more powerful computers in smaller footprints were developed, helping to permit the creation of more sophisticated digital programming. Building off the numerical control foundation, CNC took form and became a more powerful, adaptive, and sophisticated control mechanism that can offer highly repeatable process steps and monitor the quality of the machined workpiece to assure that it meets the dimensional tolerances of the programmed part design.

Learn More

CNC machining as a manufacturing process and service is available worldwide. You can readily find CNC machining services in Europe, as well as in Asia, North America, and elsewhere around the globe.

Learn More

Our experience in plastic part design and machining allows us to recognize the specific requirements of various industries and the ability to take on any plastic machining challenge. Equipped with state-of-the-art CNC machining equipment, our team of experts is capable of performing many different types of machining processes to execute the best manufacturing plan for your plastic parts.

Learn More

Brass is a metal commonly used in various industries due to its various desirable properties. The alloy contains copper, zinc, and other metals such as magnesium, iron, and lead. These metals all contribute to their properties, and, the inclusion of lead makes it very machinable.

Learn More

CNC machining it is capable of consistently producing robust parts from a very wide range of materials. CNC machines can handle almost any engineering material.

Learn More

CNC machining is ideal for one-off manufacturing jobs and for low-to-medium volume production of several hundred to 1000 parts. Also, you should opt for CNC machining when your parts need to have very tight tolerances.

Learn More

CNC is an acronym that stands for Computer Numerical Control. It is a term that is used in reference to either the automated specialized machinery (sometimes called machining centers) that can remove material from a stock piece (also called a workpiece or blank) or to the service that performs those machining operations.

Learn More Contact Us

Contact Us Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China

Address : No.103, Tong’an Park, Tong’an Industry Zone, Xiamen, China WhatsApp : +86 18259211580

WhatsApp : +86 18259211580 Email : roger@ppl2009.com

Email : roger@ppl2009.com IPv6 network supported

IPv6 network supported